LATEST NEWS

Press releases & Product news

Why do samples bulge during the hot mounting process?

2025-06-06

Hot mounting bulges too often? Two key adjustments to easily solve the problem!

In the process of hot mounting, everyone must have encountered such a problem: after the hot mounting is completed, a small bag will bulge on the surface of the sample, which will affect the subsequent grinding and polishing and the final metallographic structure observation. Today we will completely solve this annoying bulging problem.

Why does bulge appear?

In fact, the reason is very simple, mainly two points:

1. Insufficient curing time: The resin was taken out before it was completely cured, and the internal stress was released, resulting in bulging

2. Insufficient pressure: The pressure during mounting was too small, the powder was not fully compacted, leaving gaps

The solution is very simple, just adjust two parameters:

Extend the curing time: generally add 1-2 minutes to allow the resin to fully cure

Appropriately increase the pressure: adjust according to the size of the sample to ensure that the powder is fully compacted

Practical tips

1. Different brands of mounting materials may have different curing times, so it is recommended to do a small sample test first

2. Apply pressure evenly to avoid excessive or insufficient local pressure

3. Cool to below 60℃ before opening the mold to effectively reduce deformation

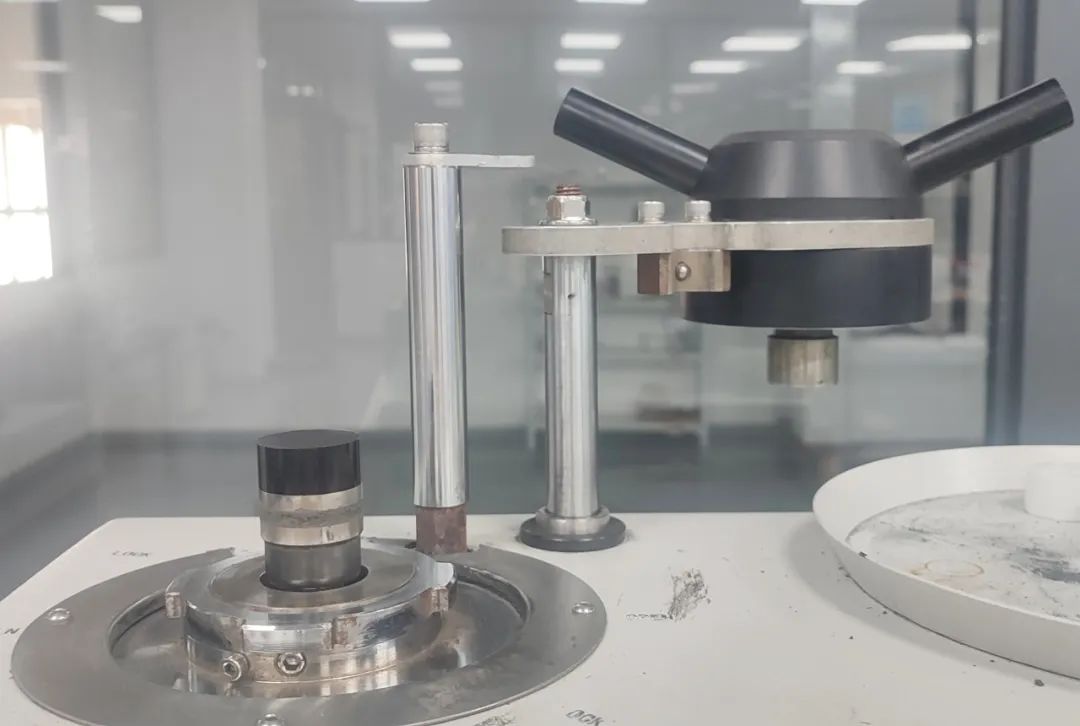

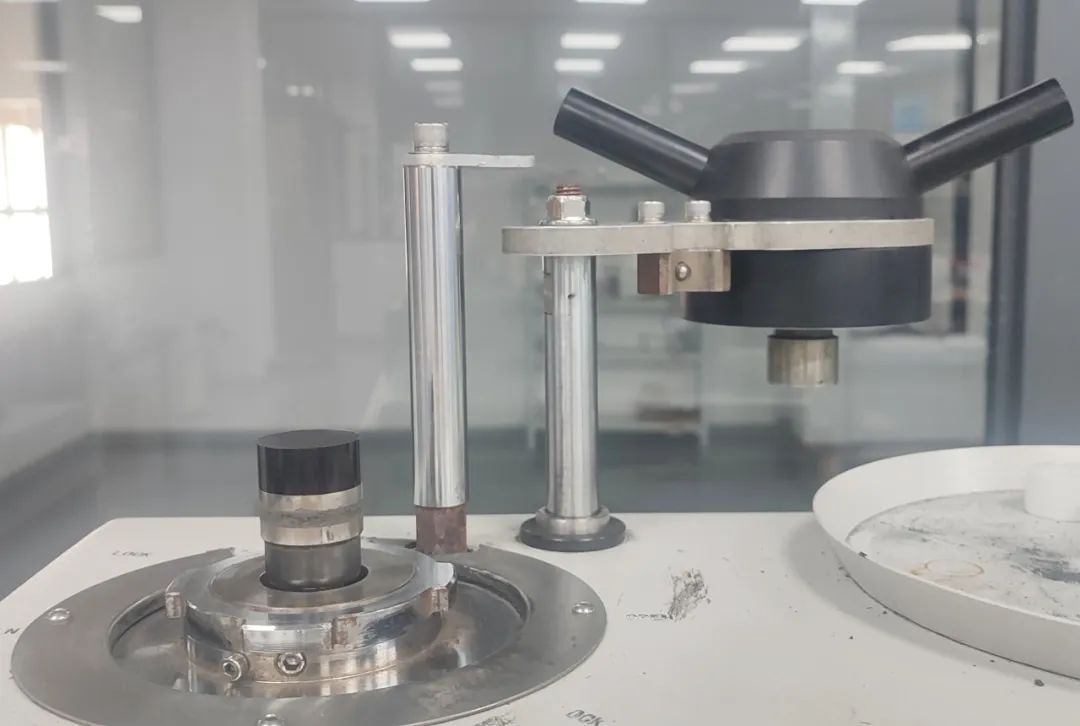

LABTT provides a series of hot mounting consumables with multiple types to choose from, such as edge-preserving type, conductive type, etc., which are suitable for different materials such as metals, ceramics, electronic components, etc., and combined with the fully automatic mounting press produced by LABTT, sample preparation can be completed quickly.

The hot mounting resin produced by LABTT has a low shrinkage rate, which can effectively reduce sample deformation; high hardness, ensuring that the edges remain intact during grinding and polishing; strong bonding with the sample, the surface of the sample after mounting is smooth and flat, without any gaps or defects, and high cost performance and low cost, making it an excellent choice for mounting samples.

Next time you make hot mounting samples, remember to adjust these two parameters to ensure that your sample is flat and perfect!