LATEST NEWS

Press releases & Product news

LABTT shines at Suzhou Heat Treatment Conference and wins the title of industry honorary enterprise

2025-06-06

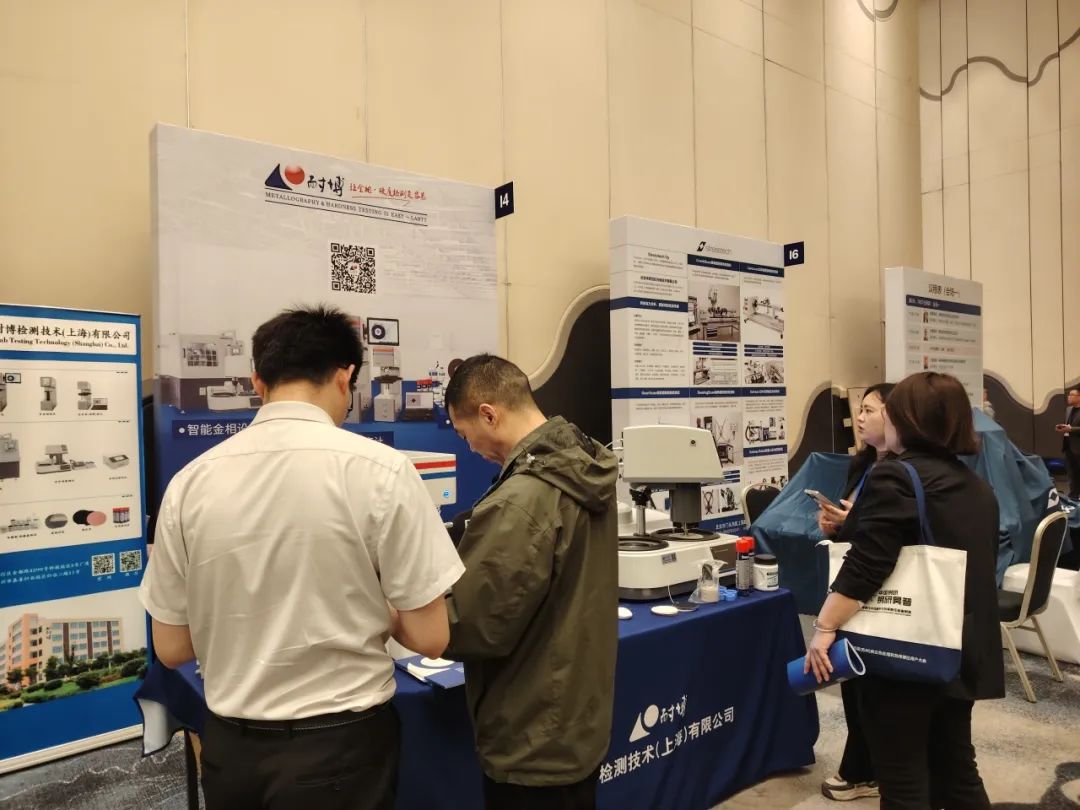

The 4th (Suzhou) Commercial Heat Treatment, Hot Isostatic Pressing, Powder Metallurgy and 3D Printing User Conference was grandly held on March 27, 2025. As one of the most influential material processing technology summits, this exhibition brought together many top companies and industry experts to discuss technological innovation and industrial upgrading in the field of high-end manufacturing.

LABTT Precision brought a number of innovative products to the exhibition, becoming the focus of the exhibition with its hard-core technical strength. Its exhibited automatic light-curing cold mounting machine, micro hardness tester and grinding and polishing machine equipment attracted many experts, scholars and industry customers to stop and communicate with them due to their advanced technology and excellent performance.

01 Automatic light-curing cold mounting press

LABTT's newly launched LUM-6000S automatic light-curing cold mounting press is a revolutionary product. It uses a unique low-temperature mode, and the temperature does not exceed 50 degrees Celsius during the sample mounting process, which can effectively protect temperature-sensitive materials.

At the same time, the mounting chamber door is electrically closed, and the closing process is smooth, reducing operational errors; after the mounting is completed, the mounting chamber door automatically opens and closes; accompanied by sound and light reminders, it improves the operating experience in all aspects, making the mounting work easy and efficient.

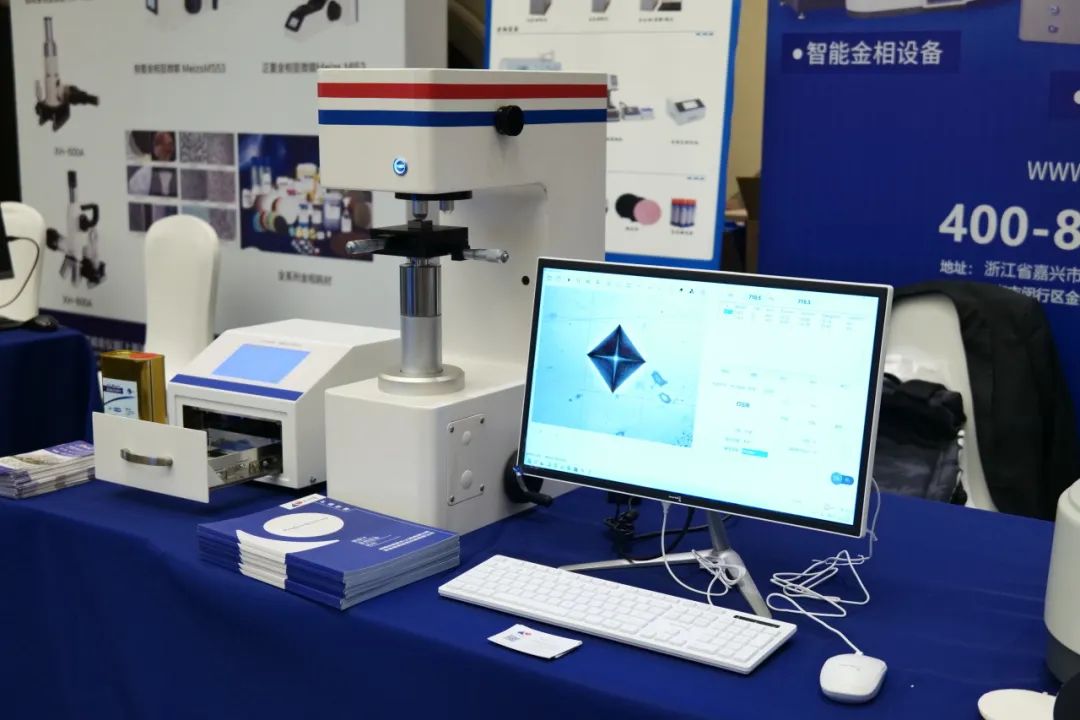

02 Hot sale microhardness tester

The THV-1MPE microhardness tester exhibited this time is also an innovative product of LABTT. Its integrated minimalist appearance design is simple yet elegant, and perfectly combines beauty and practicality. The built-in 5 million high-definition camera can present a clearer image without missing any details.

It is equipped with a brand computer and special control measurement software as standard, providing users with a convenient and efficient data processing and analysis experience. The unique optical cross-guide lifting system ensures the guiding accuracy. When the sample is lifted or lowered, the indentation is precisely focused and the image position remains unchanged, providing a solid and reliable guarantee for hardness measurement.

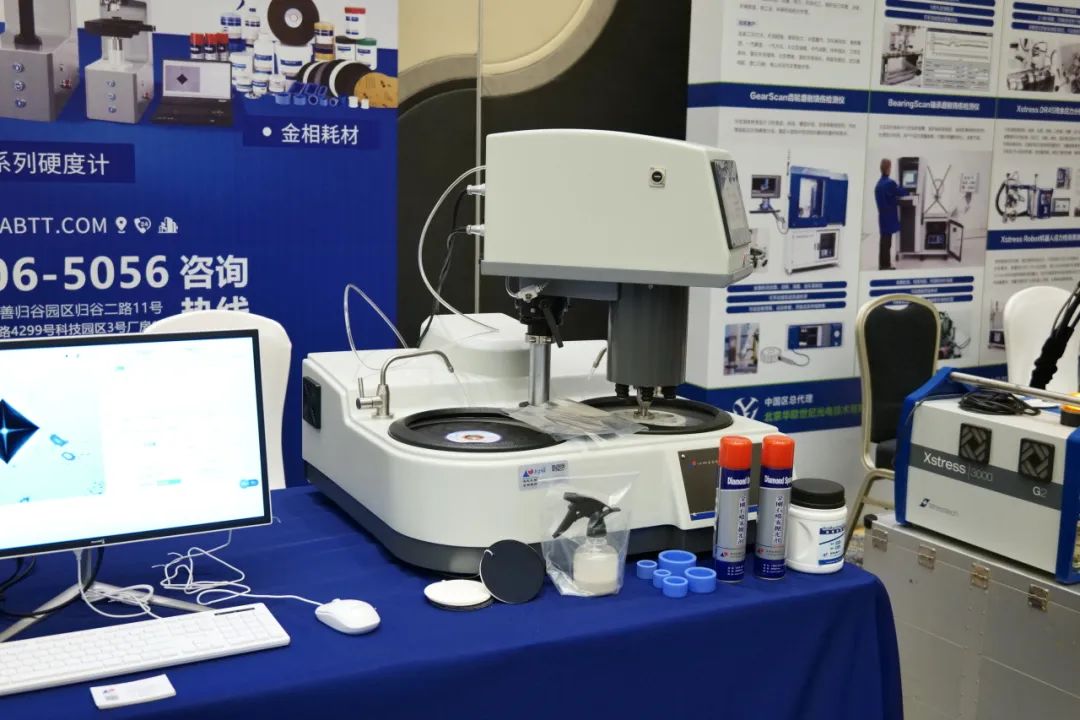

03 Fully automatic metallographic grinding and polishing machine

The LAP-2000 fully automatic metallographic grinding and polishing machine is the star product of LABTT. The equipment can clamp six samples at a time, and each sample can be individually polished to meet the diverse polishing needs. At the same time, it can also be equipped with a four-channel automatic dripper, and the entire process from grinding to polishing can be fully automatic.

In terms of power, it uses a 1KW high-power servo motor (2*1KW optional), regardless of the speed, the torque is large and constant; in terms of speed, from 0 rpm to 1000 rpm (maximum 1500 rpm), it can easily handle the polishing of samples of various materials, providing stable and reliable support for metallographic preparation.

04 Metallographic consumables

In addition to core equipment, LABTT also provides a complete metallographic testing consumables system, covering the entire process from sample cutting, mounting, grinding and polishing to polishing. This one-stop solution provides a solid guarantee for metallographic testing and demonstrates LABTT's deep technical accumulation in the field of material testing.

During the exhibition, LABTT was awarded the title of "Honorary Enterprise" by the conference for its excellent product performance and innovation ability. This honor is not only a recognition of LABTT's technical strength, but also highlights its leading position in the industry.

In the future, LABTT will continue to deepen its research in the field of material testing, driven by innovation, to provide customers with better products and services, and to promote the high-quality development of the industry. Welcome to continue to follow LABTT to get more product information and technical support!