LATEST NEWS

Press releases & Product news

A pinnacle showdown! LABTT sponsors the National College Metallography Competition Finals, witnessing the power of the new generation of materials scientists.

2025-07-30

From July 25th to 29th, the 14th National College Metallography Skills Competition and the 3rd National College Metallography Conference, sponsored by LABTT, concluded successfully in a vibrant academic atmosphere.

This top-tier competition, bringing together elite students from universities nationwide, presented a pinnacle showdown of materials science and practical skills.

Using competition to promote learning, building friendships through skills: A Review of Event Highlights

This year's competition featured a challenging and innovative program, divided into two major sections: the Metallography Skills Competition and the Metallography Conference, encompassing individual and team competitions, practical exercises, and other multi-faceted competitions.

The Metallography Conference Finals kicked off first, with contestants showcasing their superb skills in sample preparation and fiercely competing based on their solid professional foundation.

The opening ceremony of the Metallography Skills Competition brought the atmosphere to a climax. Shortlisted contestants from top universities nationwide then engaged in a thrilling two-day finals featuring grinding, polishing, etching, and inspection.

The Metallographic Conference team competition also lasted two days. Representative teams from various universities joined forces, showcasing their teamwork and collaborative spirit to the fullest.

Finally, at the grand closing ceremony, official representatives presented certificates of honor to the winning contestants and teams, bringing this five-day materials science event to a successful conclusion.

LABTT Supports: Empowering the Future of Materials with Technology

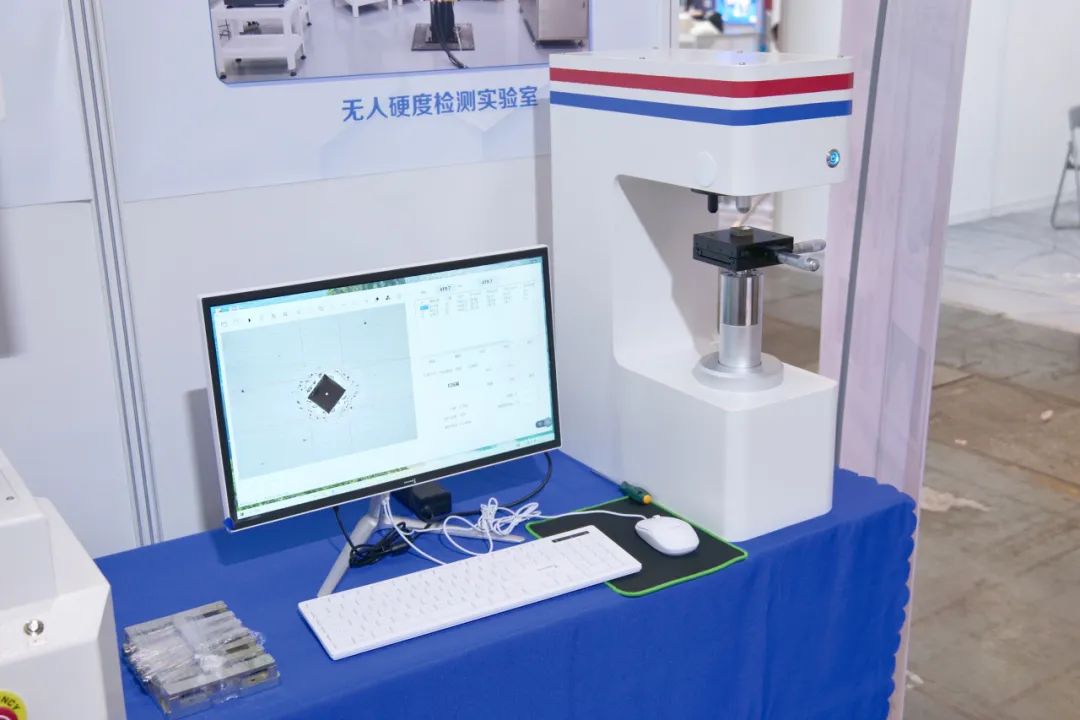

As a strategic partner of the competition, LABTT is committed to promoting technological innovation and talent development in the field of materials science. At the competition, LABTT's specially established innovation exhibition area was a focal point.

The intelligent microhardness tester amazed the audience with its ultra-high-precision measurement capabilities. Equipped with a 5-megapixel high-definition camera, it produced detailed microscopic images. The standard computer and dedicated software enabled one-click data processing, significantly improving testing efficiency and effectively avoiding measurement errors.

The fully automatic light-curing cold mounting press' low-temperature curing technology perfectly protected the structural integrity of temperature-sensitive materials. Its automated intelligent sensing system, which enabled automatic door opening and closing, as well as audio and visual notifications, sparked great interest among participating teachers and students.

LABTT representatives also introduced the company's key unmanned laboratory series to the students and faculty on site, covering key testing processes such as metallographic sample preparation, hardness testing, and microscopic analysis.

LABTT's innovative unmanned metallographic sample preparation laboratory utilizes intelligent system integration to automate the entire process, from sample cutting and mounting to grinding, polishing, and etching.

The unmanned hardness laboratory integrates three series of intelligent hardness testers: Brinell, Rockwell, and Vickers. Equipped with a high-precision robotic arm, it automates the entire testing process, from sample positioning and loading testing to data collection and analysis.

The unmanned microscopy laboratory offers fully automated testing. The intelligent robotic arm precisely adapts to various microscopes and, combined with LABTT's proprietary analysis software, enables high-precision observation, significantly improving testing efficiency and eliminating human error.

These cutting-edge devices, embodying LABTT's latest scientific research, not only demonstrate the company's technological strength in materials testing but also provide a window for university teachers and students to gain access to cutting-edge industry technologies. LABTT, committed to its mission of "making metallographic and hardness testing easier," has built a comprehensive product portfolio encompassing hardness testers, metallographic equipment, and metallographic consumables, dedicated to providing innovative and efficient testing solutions for university research, quality inspection, and industrial applications. Looking ahead, LABTT will continue to collaborate with universities to deepen industry-university-research collaboration, promote technological innovation in materials testing, and jointly write a new chapter in development.