LATEST NEWS

Press releases & Product news

The 2025 National Failure Analysis Conference was grandly held. LABTT and Shangshan Institute jointly released the results of intelligent unmanned inspection technology.

2025-08-18

From August 10th to 12th, 2025, the 2025 National Failure Analysis Academic Conference was held in Beijing. This prestigious academic event brought together experts, scholars, and industry representatives from top domestic universities, research institutions, and enterprises. They presented presentations on industry-related hot topics, aiming to jointly promote the innovative development of failure analysis technology and industrial upgrading.

At the conference, the report "Design and Practice of Intelligent Unmanned Metallographic Inspection Technology," jointly released by LABTT and the Shanghai University (Zhejiang) Institute of Advanced Equipment Basic Materials (hereinafter referred to as "Shangshan Institute"), was a highlight and garnered widespread attention from the industry.

In his keynote speech, Professor Xu Jing of Shanghai University provided an in-depth explanation of the latest research findings of the "Materials Testing Joint Laboratory" established by LABTT and SSI: an integrated intelligent unmanned inspection solution. This solution addresses the pain points of the traditional failure analysis industry in terms of efficiency, accuracy, and consistency. By integrating artificial intelligence, automation, and metallographic equipment, it achieves intelligent upgrades across the entire metallographic inspection process.

The unmanned metallographic sample preparation laboratory utilizes intelligent system integration to automate the entire process, from sample cutting and mounting to grinding and polishing to corrosion. This significantly improves work efficiency while ensuring sample preparation accuracy, providing a standardized intelligent solution for materials testing.

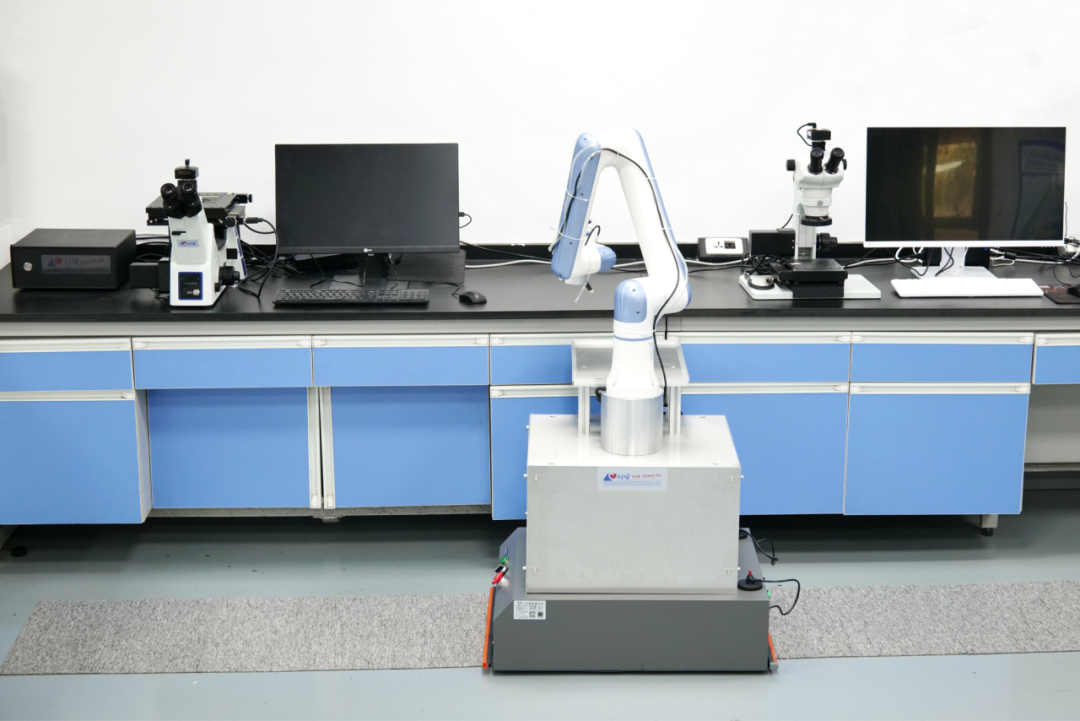

The unmanned microscopy laboratory offers fully automated testing. An intelligent robotic arm precisely coordinates with Naibo's fully automated metallographic microscope to automatically grasp samples, focus, raise and lower the sample stage, and move the platform. This significantly improves testing efficiency and eliminates human error, significantly enhancing the efficiency of both scientific research and industrial testing.

The unmanned hardness laboratory innovatively integrates three intelligent hardness testers: Brinell, Rockwell, and Vickers. Working in concert with high-precision robotic arms, these testers can be flexibly configured to meet diverse testing requirements, enabling unmanned testing throughout the entire process, from precise sample positioning to hardness testing and data analysis.

Going forward, LABTT will continue to deepen technological innovation, focusing on breakthroughs in key automation and intelligent technologies in failure analysis. By increasing R&D investment and fostering industry-university-research collaboration, LABTT will create a new generation of intelligent testing solutions and lead the industry in technological advancement.

PREVIOUS: