LATEST NEWS

Press releases & Product news

LABTT sponsors the 2025 National Failure Analysis Competition Finals!

2025-08-12

On August 10, 2025, the finals of the 2025 China Undergraduate Mechanical Engineering Innovation and Creativity Competition—Failure Analysis Competition, sponsored by LABTT, were officially held at the Shahe Campus of Beihang University. The competition brought together students from top universities nationwide, experts from enterprises and institutions, and international students, presenting a high-level demonstration of failure analysis technology.

At the opening ceremony, the Failure Analysis Branch of the Chinese Society of Mechanical Engineers awarded Academician Zhong Qunpeng and Academician Li Helin with lifetime achievement honors.

Competition Highlights

This Failure Analysis Competition saw contestants fiercely competing across three tracks: Innovation, Creativity, and Ability. They fully demonstrated their solid theoretical foundation, exceptional practical skills, and cutting-edge innovative thinking.

Competitions in various tracks were in full swing, with contestants demonstrating and answering questions based on typical engineering failure cases, covering failure mode determination, failure mechanism identification, failure cause analysis, and solution implementation.

LABTT Supports Industry Innovation

As a leading company in China's materials analysis and testing industry, LABTT has long been committed to promoting innovative breakthroughs in failure analysis technology and cultivating high-end talent. Its sponsorship of the National Failure Analysis Competition demonstrates the company's strategic commitment to deepening collaborative innovation between industry, academia, and research.

During the competition, LABTT exhibited advanced equipment such as metallographic cutting machines, light-curing cold mounting press, metallographic grinding and polishing machines, metallographic microscopes and microhardness testers, which attracted many experts, scholars and contestants to stop and communicate, becoming an important platform for technical exchanges during the competition.

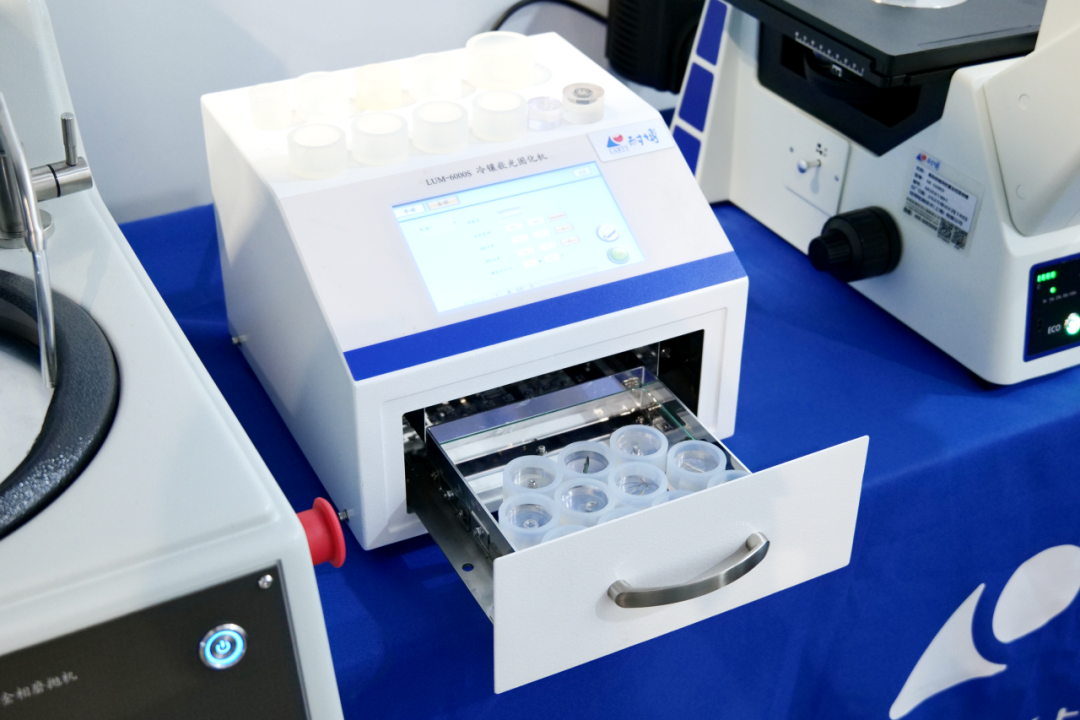

Automatic Light-Curing Cold Mounting Press

The automatic light-curing cold mounting press exhibited by LABTT utilizes a dual-wavelength combination: 365°C + 395°C (395°C + 450°C and 365°C + 450°C are optional). Each wavelength offers three independent brightness settings. Six light sources, including top, bottom, left, right, front, and back, are equipped with reflective films for uniform illumination and high curing efficiency. Furthermore, an innovative low-temperature mode keeps the sample mounting temperature below 50°C, effectively eliminating the thermal damage associated with traditional hot mounting.

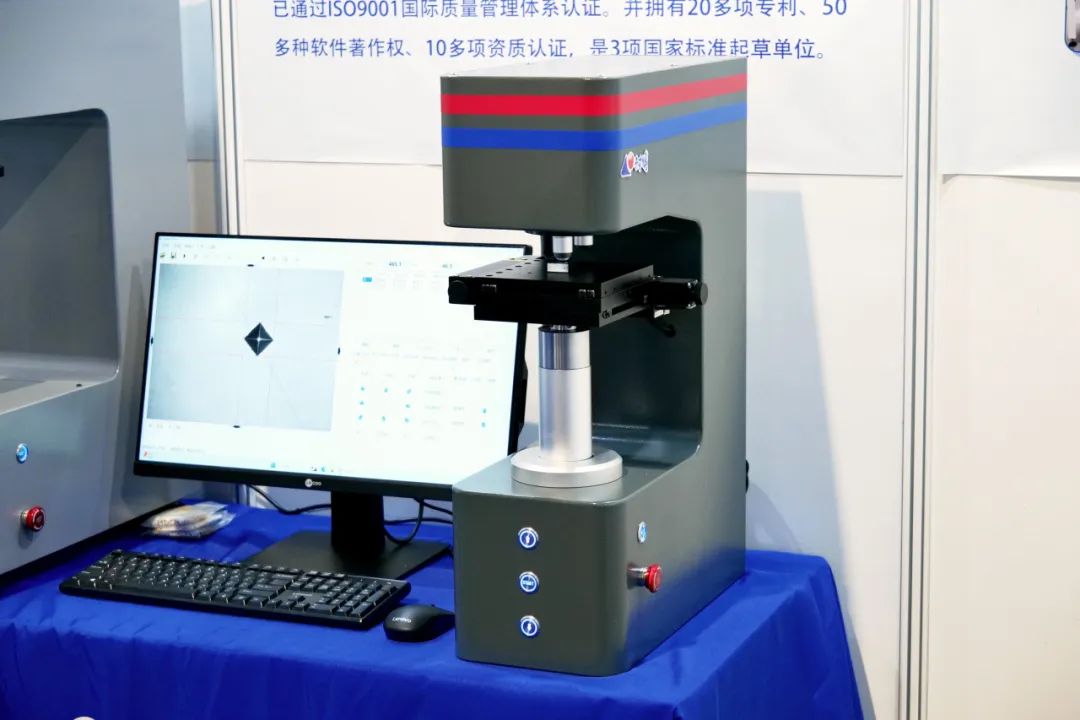

Smart Micro Vickers Hardness Tester

LABTT's flagship smart Vickers hardness tester features a built-in light source, camera, focus adjustment, and switching force mechanism. One-touch automatic focusing eliminates the need for manual positioning, and a new algorithm enables precise indentation measurement on rough or scratched surfaces. The ultra-high-precision X/Y stage boasts a repeatability of up to 1 micron, providing exceptional positioning stability and measurement reliability for hardness measurements.

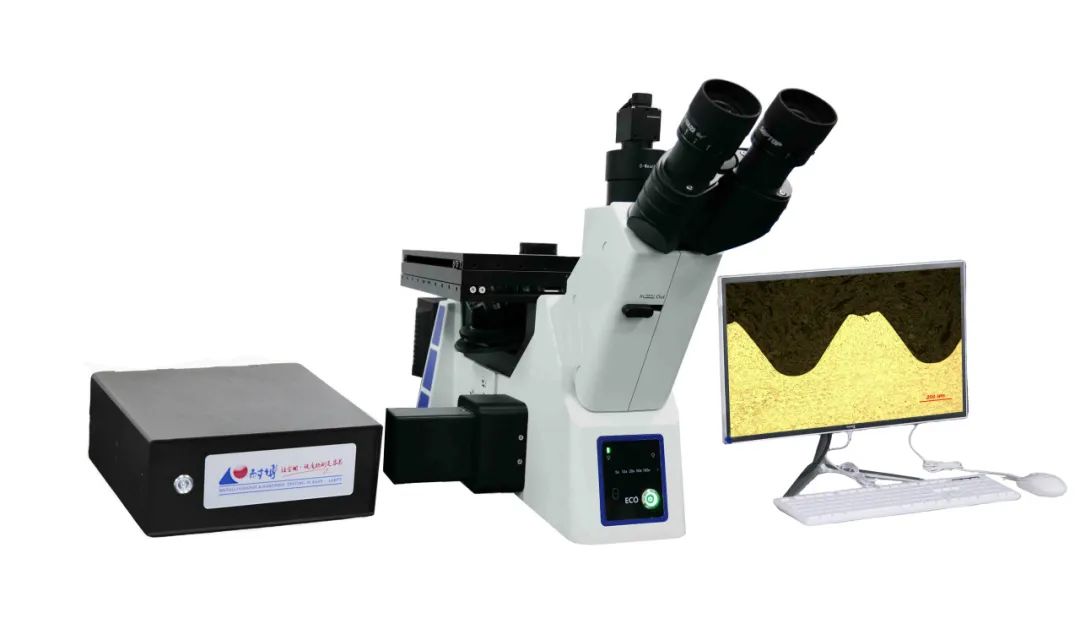

Fully Automated Metallographic Microscope

This fully automated, research-grade microscope supports multiple observation modes, including brightfield, darkfield, polarized light, and differential interference contrast, providing a comprehensive microscopic observation solution for materials analysis. Equipped with a fully automated operating system, it integrates autofocus, sample stage lift, and motion platform functions, along with a computer-controlled brightness adjustment system to ensure precise control of observation conditions. The optional automatic turret and automatic sample rotation functions enable highly automated inspection processes, significantly improving efficiency in both scientific research and industrial testing.

Looking to the Future, Striving for Common Development

LABTT's sponsorship of this competition not only provides a platform for young talent in the failure analysis field to showcase their talents, but also builds an important bridge for technological innovation and industry-university-research collaboration. We believe this will cultivate more young talents nationwide with practical and innovative capabilities in failure analysis.

LABTT founder Mr. Zhang Liqiu, one of the first certified failure analysis experts from the Chinese Society of Mechanical Engineers, has consistently led his technical team in deeply exploring future trends in failure analysis technology and jointly driving industry advancement.

In the future, LABTT will continue to deepen its commitment to the field of materials analysis and testing, and work with industry colleagues to explore the infinite possibilities of failure analysis technology!

PREVIOUS: