LATEST NEWS

Press releases & Product news

Always rework metallographic inspection? 6-step system preparation method will double your efficiency!

2025-06-19

In the field of material analysis, metallographic inspection can be called "the truth revealer under the microscope of materials". Whether it is to explore the mysteries of material organization or to meet the strict special requirements of customers, accurate and efficient metallographic inspection is the key.

But many people don’t know that the real difference between inspection efficiency and quality is often the preparatory work in the early stage. Today, we will reveal the 6 core steps to make metallographic inspection more effective, helping you avoid the "pitfall" of rework!

1. Clarify the task requirements

Confirm the analysis purpose and inspection project requirements. Is it to do material organization analysis, or to conduct scrap and failure analysis? Is it to conduct process verification? Or to complete the special requirements of the customer? Clarify the task requirements of the inspection and analysis, so that the subsequent process can be targeted.

2. Sample information collection

Basic parameters: material type (such as ductile iron), brand (such as QT400-18)

Process background: heat treatment state (such as quenching + tempering), processing technology (such as forging/casting)

Service history: use environment (such as high temperature/corrosive medium), load conditions

The more complete the information, the higher the sample preparation efficiency.

3. Equipment, consumables, and protective preparation

Instrument and equipment inspection: whether the cutting machine, mounting machine, grinding and polishing machine, metallographic microscope, microhardness tester, etc. are operating normally and in a valid calibration state.

Confirmation of consumables and reagents: whether sandpaper, mounting resin (thermosetting or cold mounting resin), release agent, polishing cloth, polishing abrasive, corrosive agent, alcohol, gasoline cleaning agent and other consumables and auxiliary materials are complete.

Goggles, anti-corrosion gloves, lab coats, ventilation facilities, chemical waste collection, etc. should be prepared in advance in case of emergency.

4. Sample processing process planning

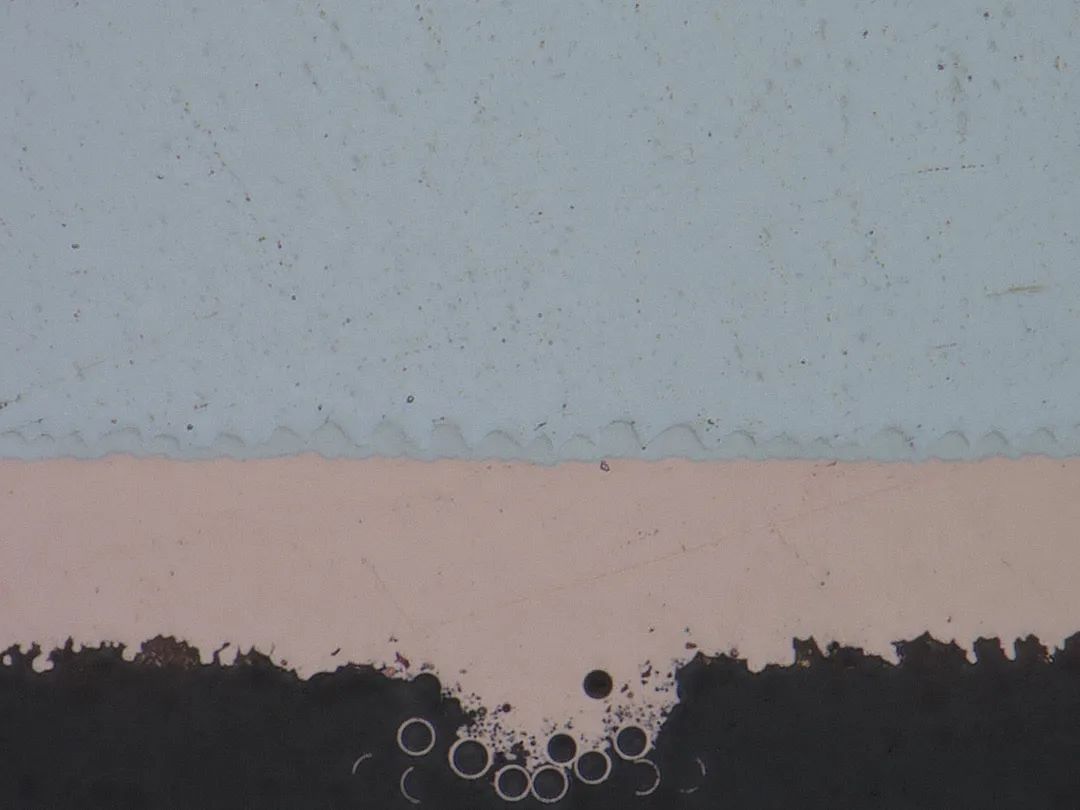

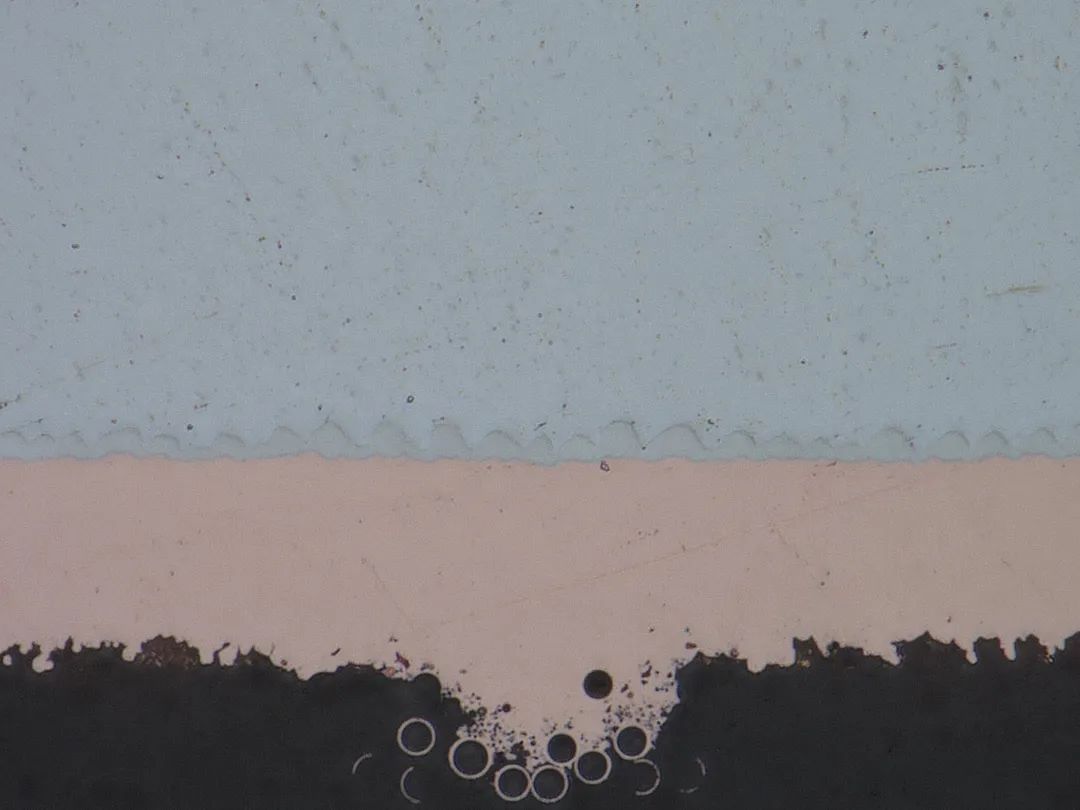

The processing processes of different samples vary greatly, and advance planning can greatly improve efficiency. For example, when analyzing multi-layer composite metal materials, the interface area can be prioritized for key grinding and polishing; for complex samples, the time-consuming steps can be reasonably allocated to different time periods.

5. Data recording, report templates, and usage standards

Standardized data recording and reporting are the guarantee of the authority of the inspection results. According to the task requirements, prepare the record form and report format in advance, and confirm the applicable inspection and analysis standards. Whether it is GB national standards or industry-specific specifications, clear standard guidelines can make data recording more rigorous and report output more professional, avoiding rework and modification due to confusing formats and inconsistent standards!

6. Backup plans and abnormal plans

If you encounter complex and special samples, consult literature or consult experts in advance. Only by knowing what you are doing can you deal with abnormal emergencies, adjust the inspection methods in time, optimize the process, and ensure the efficiency and accuracy of the analysis results.

The efficiency and accuracy of metallographic inspection are never accidental. From clarifying the task to dealing with exceptions, these 6 preparation steps are closely linked. Controlling every detail is a reflection of being responsible for the results. Next time you receive an inspection task, you might as well refer to this guide to reduce the risk of rework to zero and improve both efficiency and quality!