LATEST NEWS

Press releases & Product news

The first step in the world of metallography: cutting. How does this lay the foundation for high-quality microscopic analysis?

2025-09-22

In the complete metallographic sample preparation process, we often focus on meticulous polishing and precise etching, but often overlook the first and most crucial step: cutting. Standardized sampling directly determines the smooth progress of subsequent sample preparation and, ultimately, the authenticity and reliability of the final microscopic results.

As the saying goes, "well begun is half done." A high-quality cut sample is not only the starting point for preparation but also the data foundation for the entire metallographic analysis.

Why is cutting so critical?

The purpose of cutting is not simply to "remove" a large piece of material; it is to minimize mechanical damage and thermal effects on the material's microstructure. Improper cutting techniques can lead to:

Tissue burns: Overheating can cause changes in the metallographic structure;

Deformation layers: Introducing deep plastic deformation and microcracks;

Loss of representativeness: Sampling in the wrong position or direction fails to accurately reflect the material's state. These defects are often difficult to completely remove during subsequent grinding and polishing, ultimately appearing as "false appearances" during microscopic observation, misleading analysis and judgment.

Modern Technology Empowers: Precision Cutting Equipment

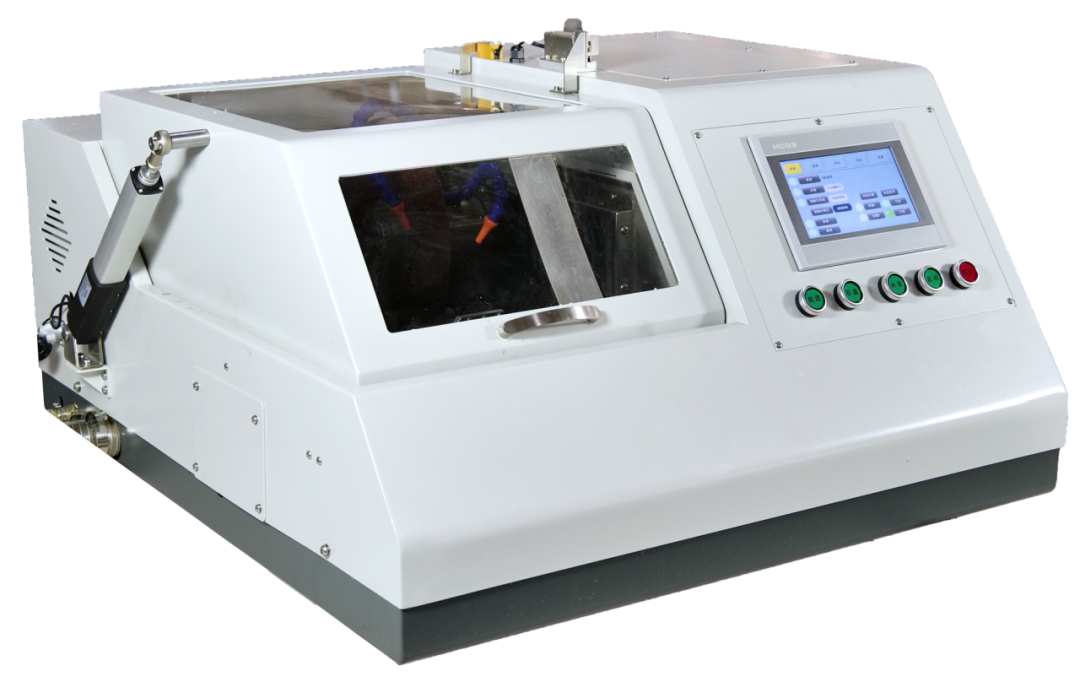

With the advancement of technology, LABTT's new generation of metallographic cutting equipment has significantly improved sample preparation efficiency and quality.

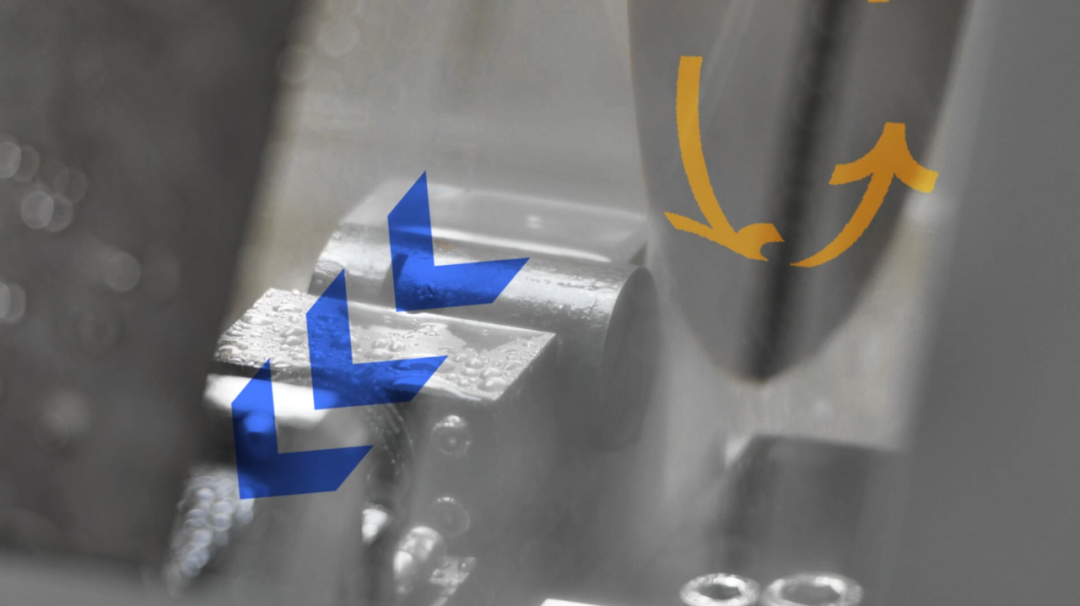

Precise Temperature Control System: Coolant control effectively prevents thermal damage to samples.

Flexible Feed Speed Adjustment: Optimizes cutting parameters for different material hardnesses, reducing deformation layers.

Stability and Automation: Reduces operator variability and ensures consistent sampling.

Flexible Fixture Design: Supports stable fixturing of complex shapes and sensitive samples.

These technological advancements from LABTT not only reduce the burden on operators but also significantly improve the repeatability, reliability, and efficiency of sample preparation. When used with LABTT's resin and diamond cutting wheels, they truly achieve the goal of "good cutting leads to good grinding and clear visualization."

A skilled craftsman must first sharpen his tools. The pursuit of efficiency and high quality in metallographic sample preparation begins with the first step: cutting. Selecting professional cutting equipment and following scientific sampling methods not only saves time but also fundamentally guarantees the accuracy of analysis.