LATEST NEWS

Press releases & Product news

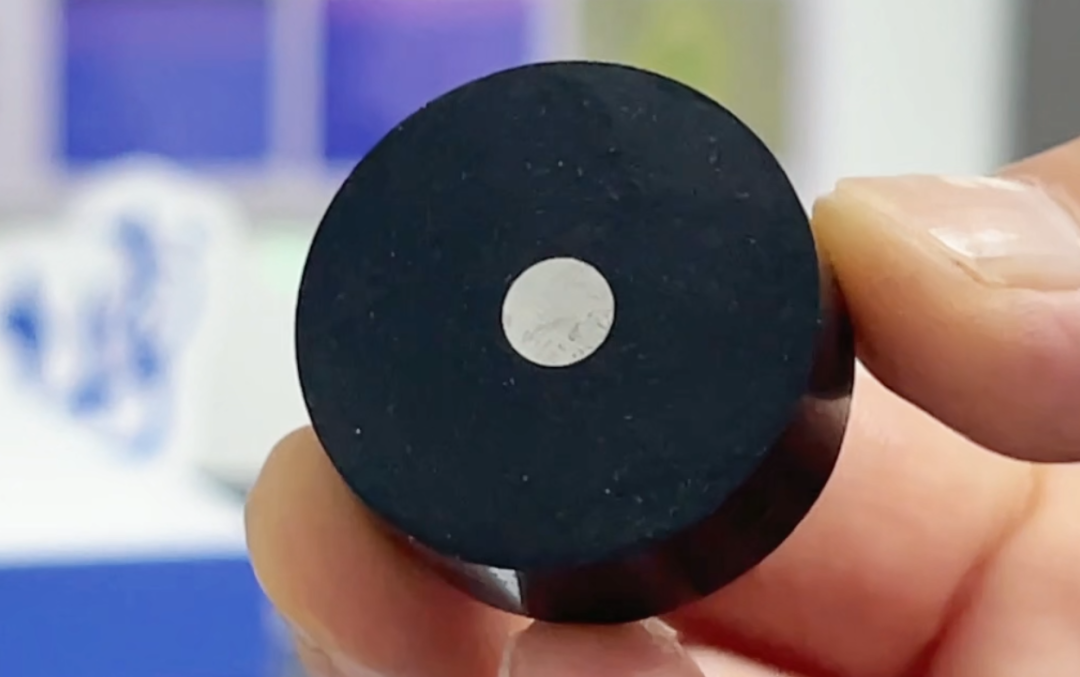

Your sample is always not smooth? Don't panic! Teach you a trick to solve the problem of "convex and concave"

2025-08-22

Have you ever encountered this problem during metallographic sample preparation? After repeated grinding and polishing, the sample surface is either raised or recessed, never achieving the desired smoothness.

This common "relief" problem can be a real headache, but don't worry! Today, we'll explain the causes in detail and provide professional and reliable solutions.

Why do samples never grind flat?

The unevenness of a sample after grinding and polishing is technically called "relief," and there are two types:

Positive relief: The sample surface is higher than the mounting material (raised)

Negative relief: The sample surface is lower than the mounting material (recessed)

Root cause:

The wear rate of the sample and the mounting resin are mismatched! If the sample is ground faster, the mounting material "wins," and the sample is recessed (negative relief); if the resin is ground faster, the sample "wins," and the mounting material is recessed (positive relief).

In short: The hardness of the resin and the sample doesn't match! But don't worry, today we'll teach you a solution!

Choose the right mounting resin!

The key to achieving a smooth surface finish is choosing a mounting resin with the right hardness. We recommend resins with high hardness and excellent edge retention, such as epoxy resin, dipropylene phthalate, and phenolic resin.

LABTT specializes in the development and production of a wide range of hot-mounting materials, including general-purpose, conductive, edge-retaining, and soluble series, to meet the mounting needs of various samples.

We particularly recommend HM3 edge-retaining hot-mounting material. Its special formula offers extremely low shrinkage and excellent sample bonding. Its high hardness and wear resistance make it ideal for samples requiring high edge protection.

For mounting, choose LABTT's "all-purpose high-hardness resin"—it can handle all metal sample preparation needs and eliminate the worry of raised or convex surfaces!

Selecting professional sample preparation materials and correct application techniques are key to achieving ideal testing results. LABTT is committed to providing customers with the highest-quality metallographic sample preparation solutions. If you have any technical questions, please feel free to contact our professional team.