LATEST NEWS

Press releases & Product news

Multifunctional Electrolytic Polishing & Etching Instrument

2025-02-08

Today, I'd like to introduce you to a powerful assistant for metallographic sample preparation – the EP-06X Electrolytic Polishing and Etching Instrument. This device combines the functions of electrolytic polishing and etching, bringing a brand-new experience to the metallographic sample preparation work.

Unique working principle

The EP-06X Electrolytic Polishing and Etching Instrument applies the exquisite principle of electrochemistry. Its DC parameters range from 0-100V/0-6A, and the current/voltage values can also be customized according to users' specific requirements.

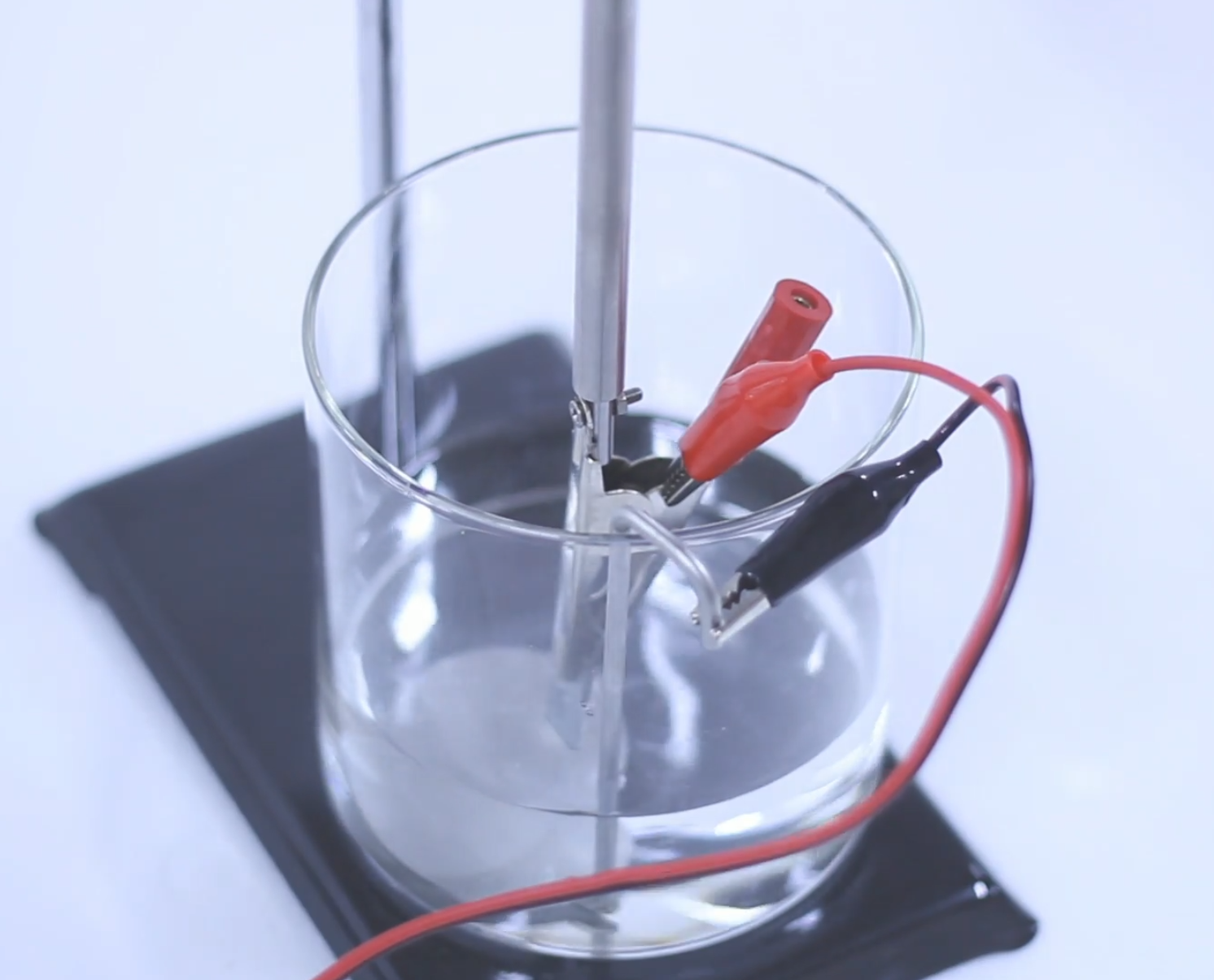

When the sample is immersed in a specific electrolyte solution and connected to the electrodes of the instrument to form a circuit, the current starts to take effect. Under the influence of the current, an electrochemical reaction occurs on the surface of the sample, achieving the effect of either polishing or etching. Eventually, the morphology and distribution of the metallographic structure can be clearly revealed.

Polishing and corrosion combined

One of the biggest highlights of this instrument is that it integrates polishing and etching functions. In the metallographic sample preparation process, it shows extremely high efficiency.

Compared with traditional machine polishing, the EP-06X electrolytic polishing and etching instrument uses electrochemical action to make the sample surface reach mirror-like finish in a short time, greatly shortening the sample preparation time and ensuring the authenticity of the material microstructure.

In the metallographic etching link, the instrument also performs well. By precisely controlling parameters such as current, voltage and corrosion time, it can accurately corrode samples of different materials and obtain clear, stable and repeatable etching effects.

Touch screen control Polarization curve measurement

EP-06X is equipped with a touch screen. Users can easily set various parameters by simply tapping the screen. Moreover, it can also display the voltage-time and current-time curves in real time, allowing the operator to have a clear view of the entire sample preparation process. This intuitive operation method reduces the difficulty of operation, and even novices can quickly get started.

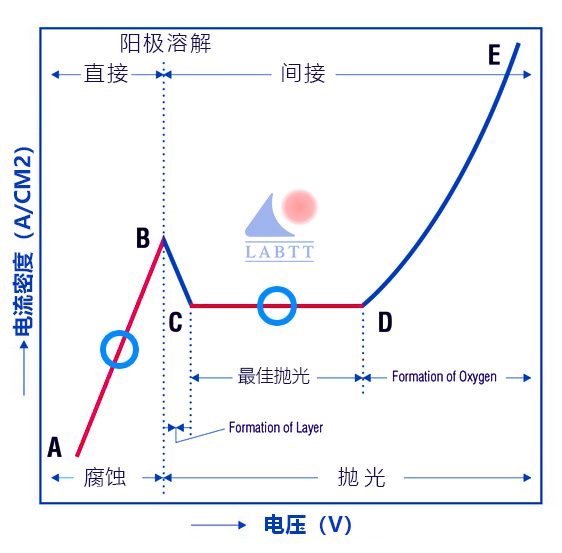

At the same time, the device can automatically measure the polarization curve through the current and voltage scanning instrument. Through the generated curve, we can accurately confirm the specific voltage and current suitable for the material, so as to obtain the best corrosion and polishing parameters. This function provides accurate and reliable reference data for metallographic sample preparation.

Flexible working mode, precise control of voltage and current

The electrolytic polishing and etching instrument can realize two working modes: constant current and constant voltage. Different materials have different requirements for electrical parameters in the sample preparation process. For example, some materials can achieve better uniform polishing under constant current conditions; while other materials have better etching effects under constant voltage.

Not only that, in terms of voltage regulation, its display accuracy can reach two decimal places, and the voltage accuracy is as high as 0.01V; the current regulation and display accuracy can reach three decimal places, and the current accuracy is 0.001A, which can effectively avoid sample preparation failure or poor quality due to parameter errors.

All-round security protection and intelligent data interaction

Safety is always an important factor that cannot be ignored in the design and use of instruments. The EP-06X electrolytic polishing and etching instrument has a complete safety protection mechanism, including power supply overvoltage, overheating, and mains input over-voltage and undervoltage protection, to ensure that the instrument can operate normally and safely, and ensure the safety of the equipment and operators.

This equipment has advanced data interaction functions, and the working voltage and current data can be accurately input into the computer, providing strong support for subsequent in-depth data analysis and research. In terms of communication methods for data transmission, in order to meet the diverse needs of different users, we provide three highly advantageous options, RS232, RS485, and wireless connection. Three connection methods can be selected to communicate with the computer.

The EP-06X electrolytic polishing and etching instrument has brought a qualitative leap in metallographic sample preparation with its advanced technology and powerful functions. It not only solves many problems of traditional sample preparation methods, but also provides more accurate and efficient means for material research and analysis. If you have higher requirements for metallographic sample preparation, you may wish to choose this electrolytic polishing and etching instrument.