LATEST NEWS

Press releases & Product news

A new revolution in metallographic grinding and polishing!

2025-02-12

As a key pre-processing step for material microscopic analysis, metallographic grinding and polishing is of great importance. In the current era of increasing pursuit of efficiency and intelligence, advanced grinding and polishing equipment has become an urgent need of the industry. LABTT has been devoted to the research of more intelligent and automated grinding and polishing systems. After unremitting efforts in innovation, the iAPS-9000 fully automatic metallographic grinding and polishing system came into being.

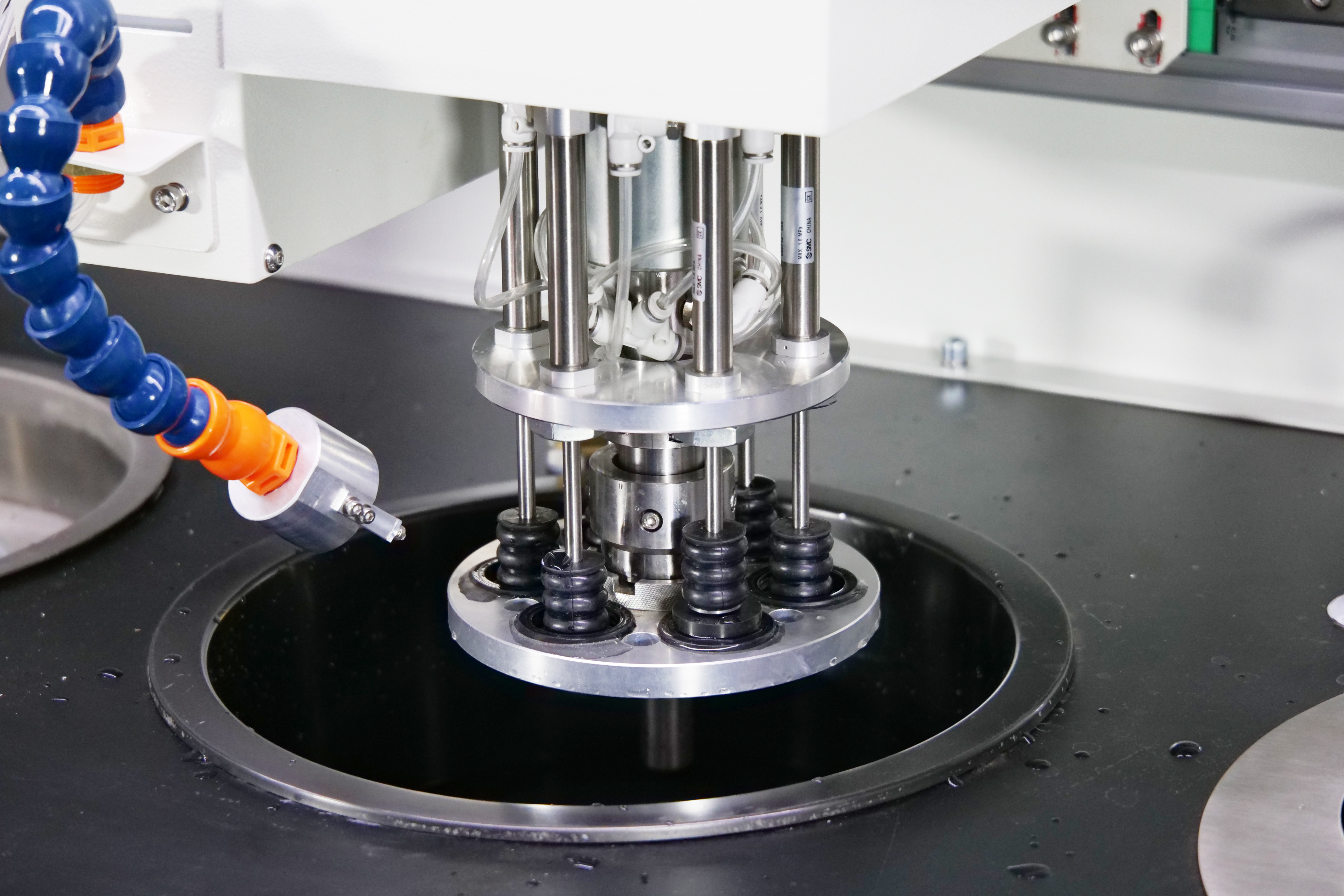

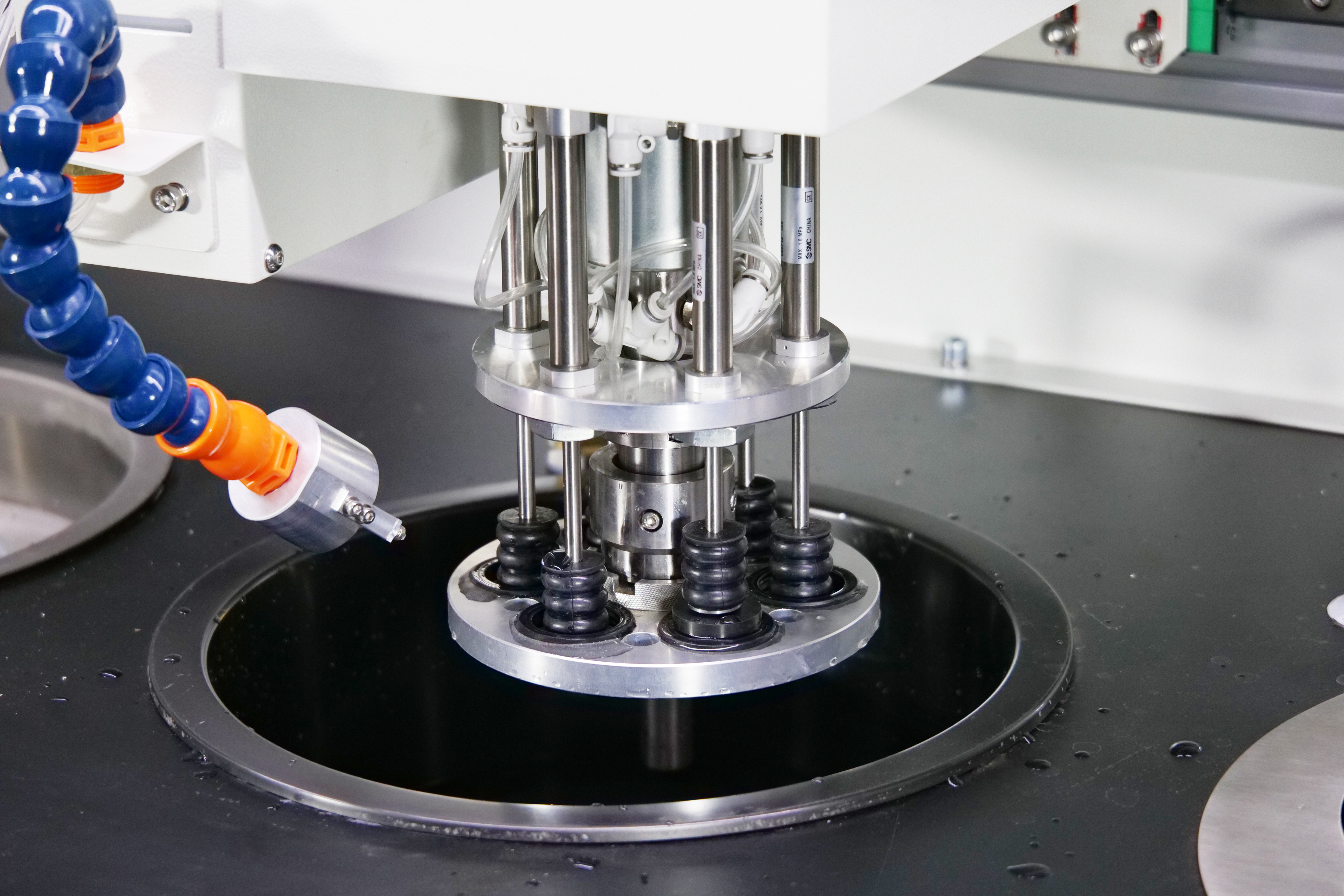

iAPS-9000 fully automatic metallographic grinding and polishing system is a fully automatic metallographic sample grinding and polishing system that can automatically clamp samples, automatically change grinding and polishing discs, and automatically clean. The system integrates three workstations: grinding and polishing, cleaning and drying, and automatic loading and unloading of samples, realizing full-process automation. It is worth mentioning that the number and functions of the workstations can be flexibly customized according to actual needs to meet the personalized production processes of different users.

Powerful functions to help efficient grinding and polishing

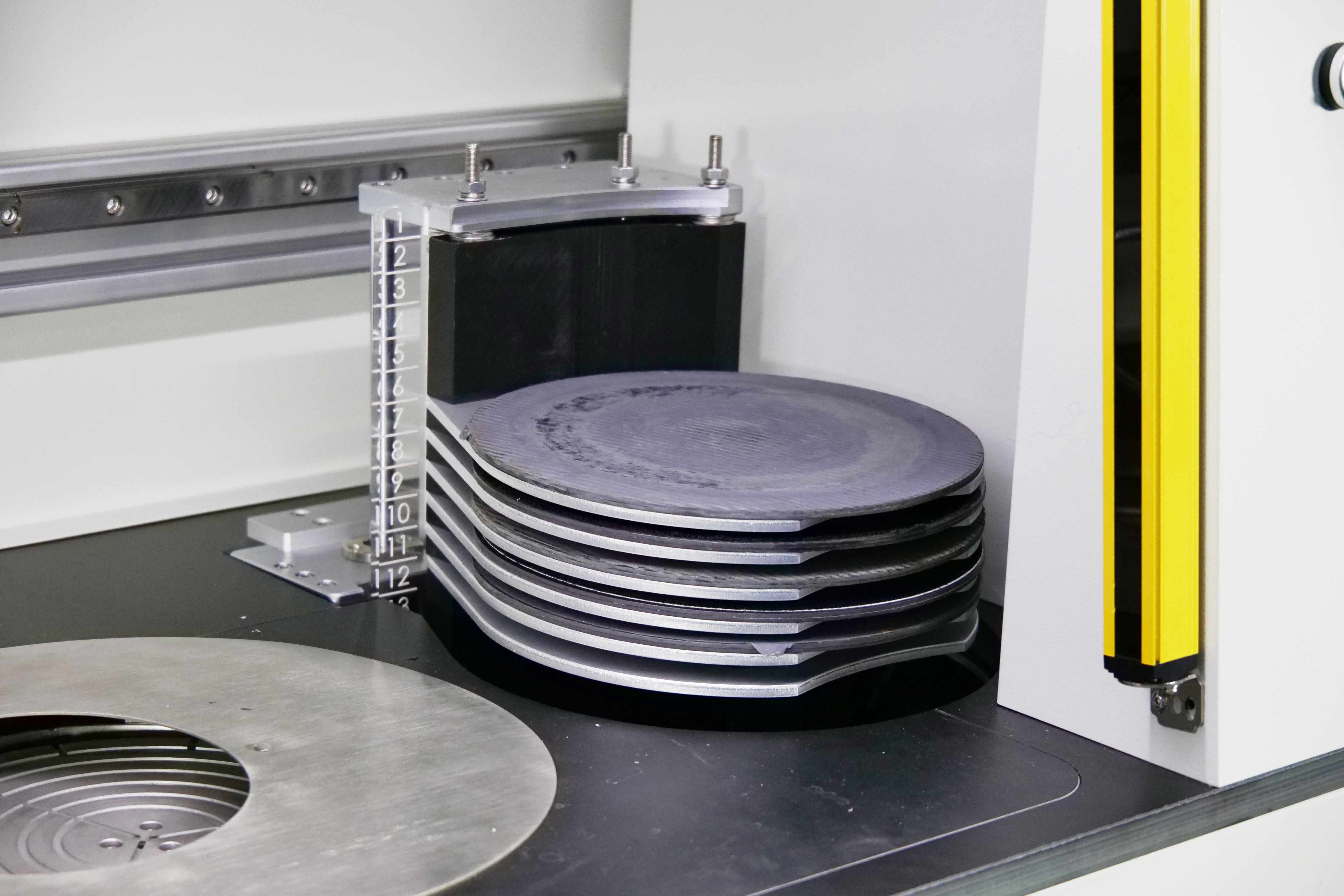

iAPS-9000, equipped with a disc changer for 9 types of grinding and polishing media, can easily replace diamond grinding discs, sandpaper and various polishing cloths to meet different process requirements. The number of disc changers can be customized.

The sample cleaning station of the polishing system is equipped with 6 water spray ports and air blowing ports, which greatly improves the cleaning and drying effect; LABTT also integrates 4 different polishing liquid adding units to provide strong support for diversified polishing operations.

Not only that, iAPS-9000 can complete the polishing of 6 samples at a time, and up to 8 samples, which makes the efficiency a qualitative leap.

Highly automated, powerful and stable

When staff use iAPS-9000 to prepare samples, the sample grinding and polishing pressure can be set digitally by software and automatically kept constant, which fundamentally ensures the stability of grinding and polishing quality. Just enter the corresponding program, the equipment can complete one station and seamlessly connect to the next station, fully automated operation, and realize intelligent workflow.

At the same time, in the single sample pressurization mode, the system can be equipped with the function of automatic clamping and unloading samples, realizing the fully automated operation of sample clamping and disassembly process.

The grinding and polishing disc uses a 1KW high-power motor with strong and constant torque. The speed range is between 5 rpm and 1500 rpm. It can be started and stopped quickly, and the turntable can stop rotating in just 2 seconds. All grinding and polishing parameters, such as speed, grinding and polishing time, rotation direction, water valve switch, etc., can be freely set and automatically saved for easy access at any time.

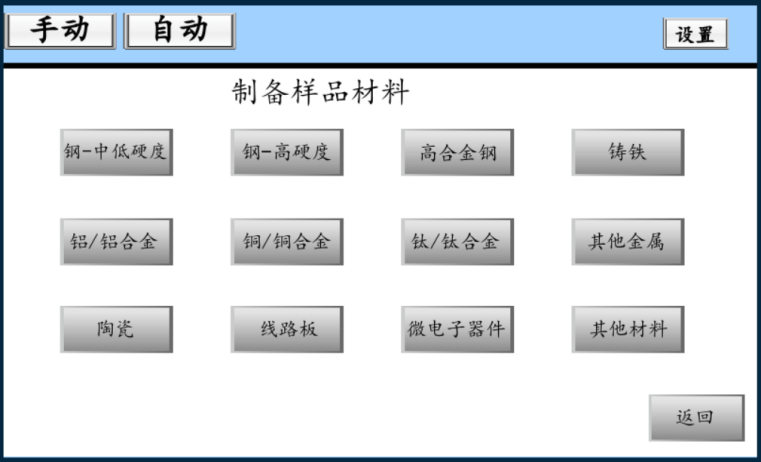

Three working modes to meet different needs

In order to better serve users, the iAPS-9000 fully automatic metallographic grinding and polishing system is carefully designed with three working modes. In the fully automatic mode, 99 sets of grinding and polishing processes can be set and called, and each station of each process has 99 grinding and polishing parameters to choose from; there is also a preparation material mode, which selects internal preset parameters according to the type of sample material; and a manual mode, which can operate a certain function of the equipment separately. The three modes complement each other and meet the diverse needs of different users in different scenarios.

At the same time, two pressurization methods are provided: single sample pressurization and sample tray pressurization. Users can freely choose according to actual needs and flexibly respond to various complex operation requirements.

Safety and convenience are equally important to ensure user experience

LABTT always puts the safety of operators first. Once the body mistakenly enters the working area during the grinding and polishing process, the equipment will automatically stop running, building a solid safety line for the operator and effectively ensuring their personal safety.

In terms of user experience, iAPS-9000 also has full marks for details. It can be equipped with a wireless mobile device controller to achieve convenient remote control; it can also be equipped with a water filtration and circulation system, which does not require an external water source and can be reused, reducing costs while also reducing the waste of water resources.

The iAPS-9000 fully automatic grinding and polishing system has become an innovator in the field of metallographic grinding and polishing with its excellent functions, high degree of automation, multiple working modes and considerate safety and convenient design. It is not only a powerful testimony to LABTT's innovative spirit and technical strength, but also an important force in promoting the metallographic grinding and polishing industry to move towards a new era of intelligence and efficiency.