LATEST NEWS

Press releases & Product news

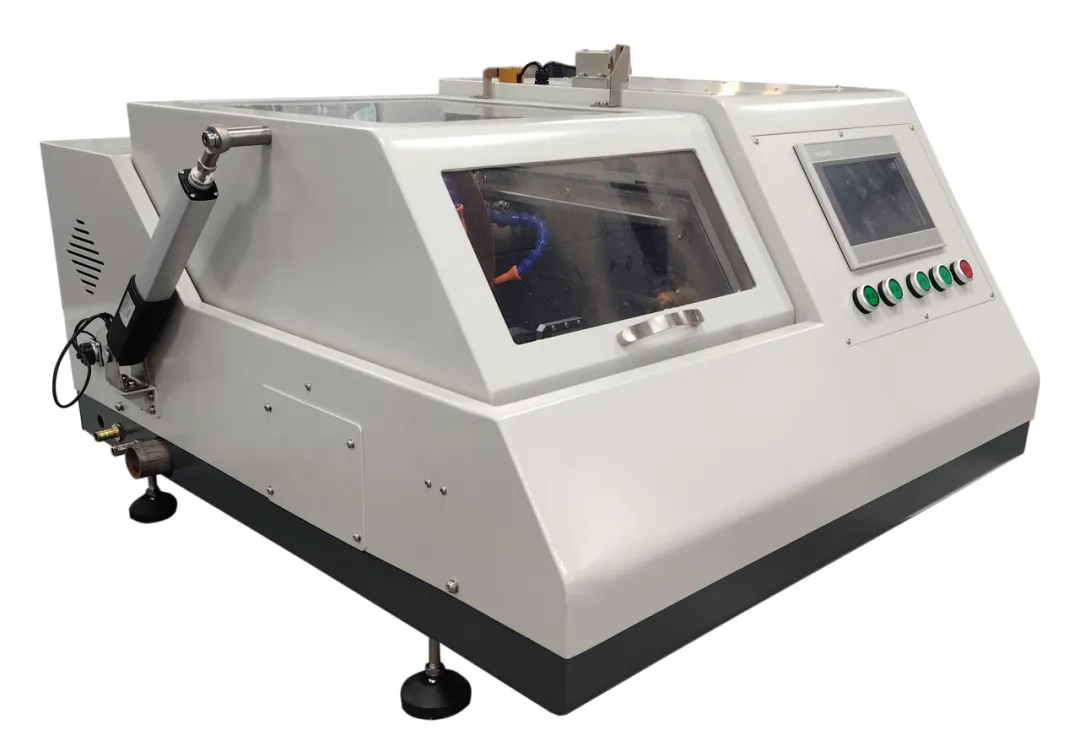

iMC-250 Automatic High-speed Precision Cut-off Machine

2025-03-03

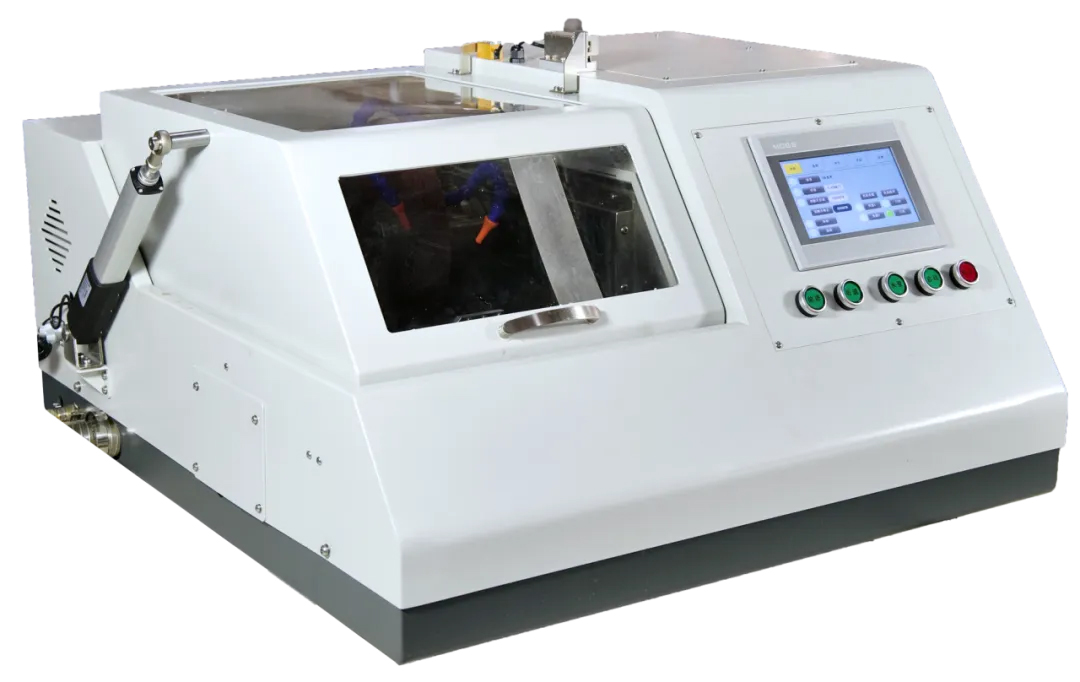

In the field of modern industrial manufacturing and scientific research, the demand for precision cutting equipment is growing day by day, and the performance of cutting equipment will directly affect the production efficiency and quality of the product. Today, we would like to introduce to you a magical tool that performs excellently in the field of cutting - the LABTT iMC-250 automatic high-speed precision cutt-off machine, which stands out with its unique design and powerful functions.

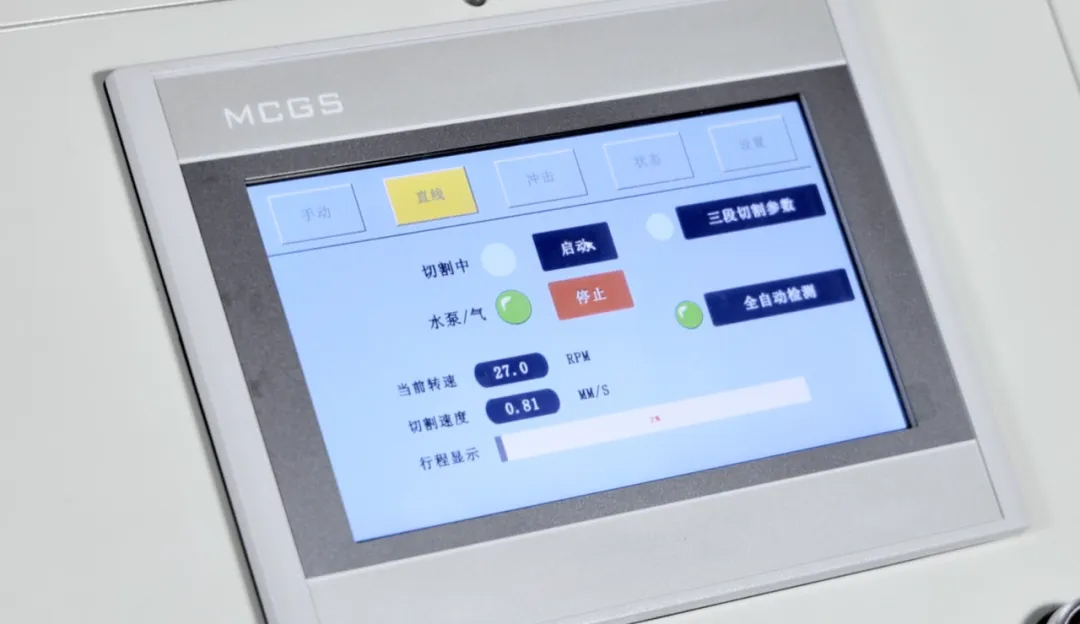

Intelligent control, precise and efficient

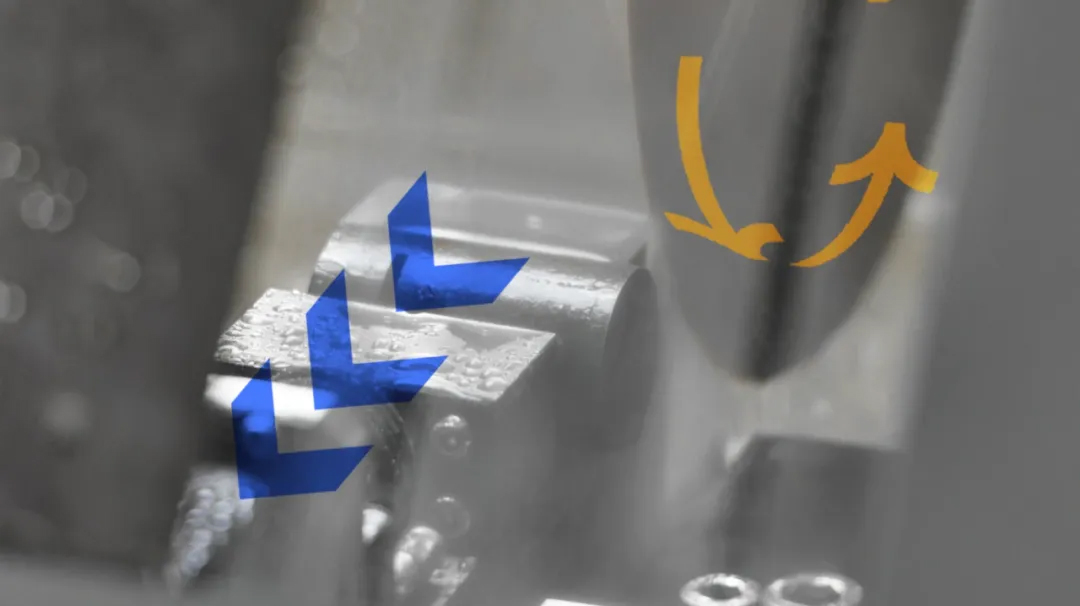

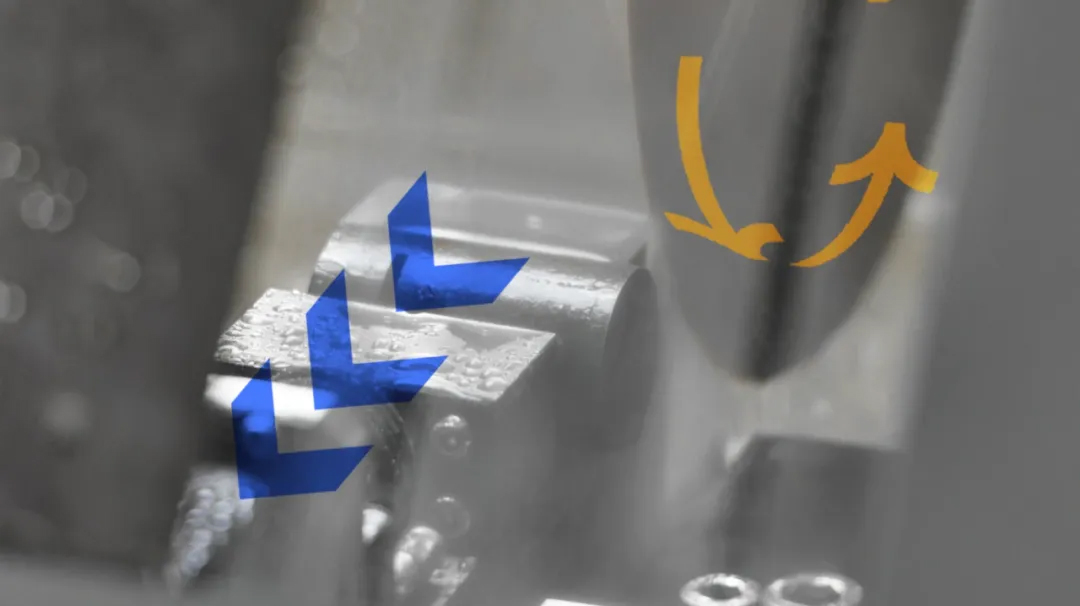

The iMC-250's innovative Y-axis intelligent cutting method is a highlight. It can automatically and quickly find the cutting starting point, automatically adjust the cutting speed, and set the maximum speed limit according to the load. It automatically ends the cutting after the cutting is completed, greatly improving the cutting efficiency and accuracy. At the same time, it also retains the traditional Y-axis manual, automatic, impact and other cutting methods to meet the operating habits and special needs of different users.

Diverse functions and flexible adaptation

This cutting machine has a wealth of optional functions. The automatic/manual X-axis parallel movement sample function can achieve parallel cutting of samples, especially the automatic X-axis parallel movement function, which can automatically complete parallel sample cutting once started; the dual-blade simultaneous cutting option can obtain samples with two parallel sides at one time; the automatic sample rotation cutting option effectively reduces sample heating and ensures that the sample is not affected by high temperature during the cutting process. These diverse functions enable it to flexibly adapt to various complex cutting tasks.

Convenient design, perfect experience

From the user's perspective, the iMC-250 is also equipped with a series of convenient device options. The automatic door opening and closing device makes it easier to open and close the door; the automatic sample clamping device has a large clamping force of 240N, making sample loading easy and convenient; the automatic flushing device of the cutting chamber automatically flushes after cutting is completed, and can also be manually controlled to keep the equipment clean. In addition, the setting parameters can be stored, and up to 99 sets of cutting processes can be saved without having to reset them each time, which greatly saves operation time and energy.

Thoughtful details, worry-free use

Some humanized details also make the iMC-250 stand out. The sample collection net can prevent small samples from falling, avoiding material waste and environmental pollution; the language switching function between Chinese and English is convenient for users from different countries and regions, and it is truly international and universal.

In terms of safety, the iMC-250 is very thoughtful. The built-in external circulation water cooling device can not only ensure the stability of the cutting process, but also prevent the equipment from overheating and causing problems. The closed transparent protective cover and safety switch provide all-round protection for the operator, effectively avoiding possible accidental injuries during the cutting process.

The iMC-250 automatic high-speed precision cutting machine has shown strong competitiveness in the cutting field with its advantages in intelligent control, diverse functions, convenient design, safety protection and thoughtful details. If you are worried about finding a high-performance cutting device, you might consider the iMC-250. I believe it will bring you unexpected surprises!