LATEST NEWS

Press releases & Product news

How to measure the hardness of curved samples

2025-06-03

In the field of hardness measurement, the shape and surface characteristics of the sample will directly affect the accuracy of the measurement results. Especially for samples with curvature (such as round bars, pipes, etc.), if the conventional platform is used for measurement directly, the results will often be biased. So, how to correctly measure the hardness of such samples? This article will explain it in detail for you.

Why can't samples with curvature be measured directly?

The contact surface between the curved sample and the hardness tester indenter is not flat. If it is placed directly on an ordinary platform for measurement, the following problems will occur:

Insufficient contact: The contact area between the sample and the platform is small and easy to slide.

Data deviation: The curved surface will cause uneven force on the indenter.

Risk of equipment damage: Unstable samples may damage the indenter.

How to accurately measure curved samples?

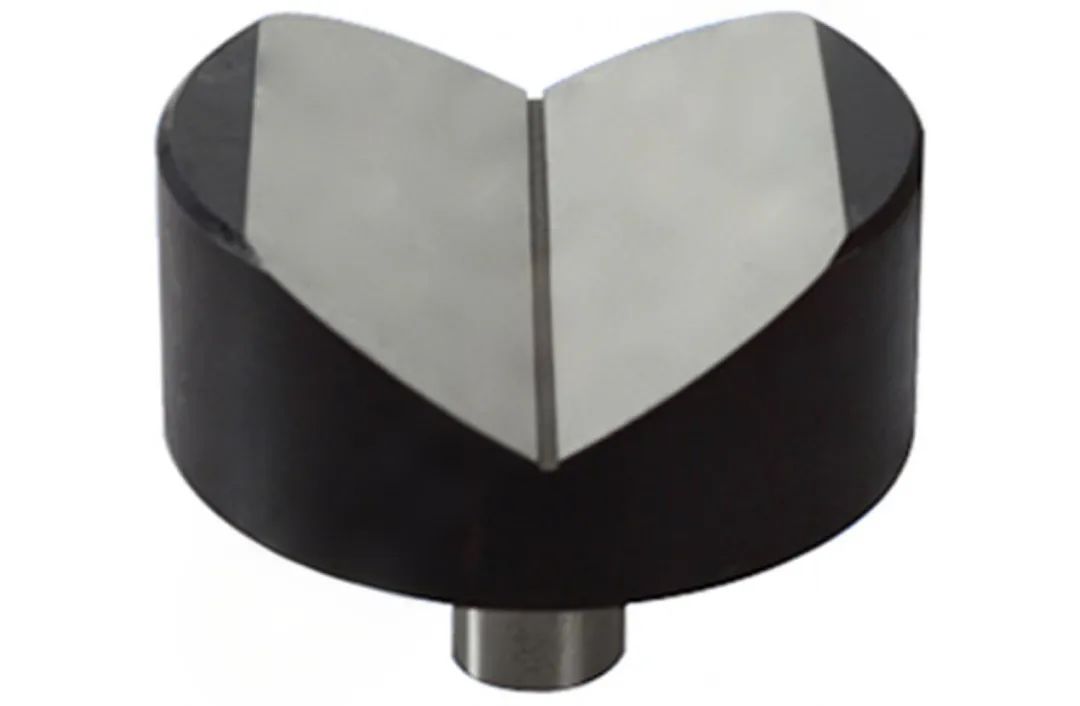

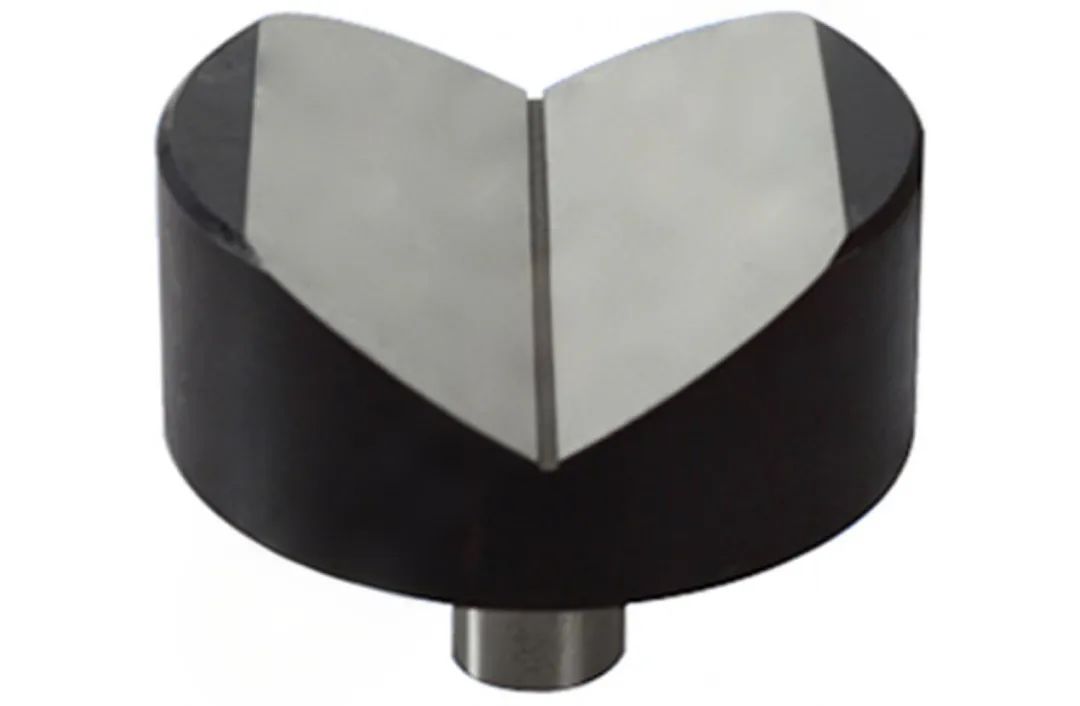

1.Use a V-shaped test bench

For curved samples such as round bars and tubes, the V-shaped test table is an indispensable tool. The test table can perfectly fit the curved surface to ensure that the sample remains stable during measurement and avoids sliding or tilting.

Operation steps:

Remove the ordinary platform and replace it with a V-shaped test table.

Place the round bar sample steadily in the V-shaped groove to ensure a stable contact surface.

Adjust the sample position so that the measurement point is at the top of the arc to obtain the best contact effect.

2.Choose a Vickers hardness tester

Vickers hardness tester is an ideal device for measuring curved samples. The micro Vickers hardness tester produced by Naibo can measure more conveniently and quickly:

One-key measurement: simple operation, just press a button to complete the measurement.

High precision: comes with measurement software, automatically measures the hardness value.

Multi-function fixture: equipped with a variety of test bench fixtures, easily handle various samples.

3.Precautions during measurement

Sample cleaning: Ensure that there is no oil, oxide layer or other impurities on the sample surface before measurement.

Pressure selection: Select the appropriate test force according to the sample material to avoid overload or inaccurate measurement.

Multiple measurements: It is recommended to select multiple measurement points on the same sample to improve data reliability.

Summary:

Through the correct operation steps above, you can easily obtain accurate measurement results. Hardness measurement requires not only professional equipment, but also standardized operation and attention to detail.

Follow us to master more hardness tester usage skills and improve your measurement efficiency and accuracy!

If you have more questions about hardness measurement, please leave a message for consultation!