LATEST NEWS

Press releases & Product news

What is the hardness tester used for?

2025-06-03

In the field of material science and industrial manufacturing, hardness is one of the important indicators for measuring material performance. As a professional measuring tool, the hardness tester can quickly and accurately evaluate the hardness of a material and provide key data support. So, what exactly is a hardness tester? What are its types? What are their characteristics? This article will answer them one by one.

The role of hardness tester

A hardness tester is an instrument used to measure the hardness of a material. It mainly uses the principles of indentation, scratch or rebound method to evaluate the material's ability to resist external indentation or scratching. The hardness value not only reflects the strength, wear resistance and toughness of the material, but also indirectly determines the processing performance and service life of the material. Hardness testers are widely used in the testing of metals, ceramics, plastics, rubber and other materials. They are indispensable tools for manufacturing, scientific research institutions and quality inspection departments.

Types and characteristics of hardness testers

Depending on the measurement principle and application scenario, common hardness testers are mainly divided into the following categories:

1. Brinell Hardness Tester (HB)

Principle: A steel ball or carbide ball of a certain diameter is pressed into the material surface, and the indentation diameter is measured to calculate the hardness value.

Features:

Suitable for soft or medium hard materials, such as aluminum, copper, cast iron, etc.

The indentation is large, and the measurement result is less affected by the surface roughness of the material.

Suitable for measuring coarse-grained materials or non-uniform materials.

Application scenarios: Casting, forging industry, and hardness testing of large workpieces.

2. Rockwell Hardness Tester (HR)

Principle: Apply test force twice through a diamond cone or steel ball indenter, measure the difference in indentation depth to calculate the hardness value.

Features:

Simple operation, fast measurement speed, suitable for large-scale testing.

Divided into a variety of scales (such as HRA, HRB, HRC), can measure different materials from soft to hard.

The indentation is small and the damage to the sample surface is small.

Application scenarios: metal processing, heat treatment industry, and hardness testing of small workpieces.

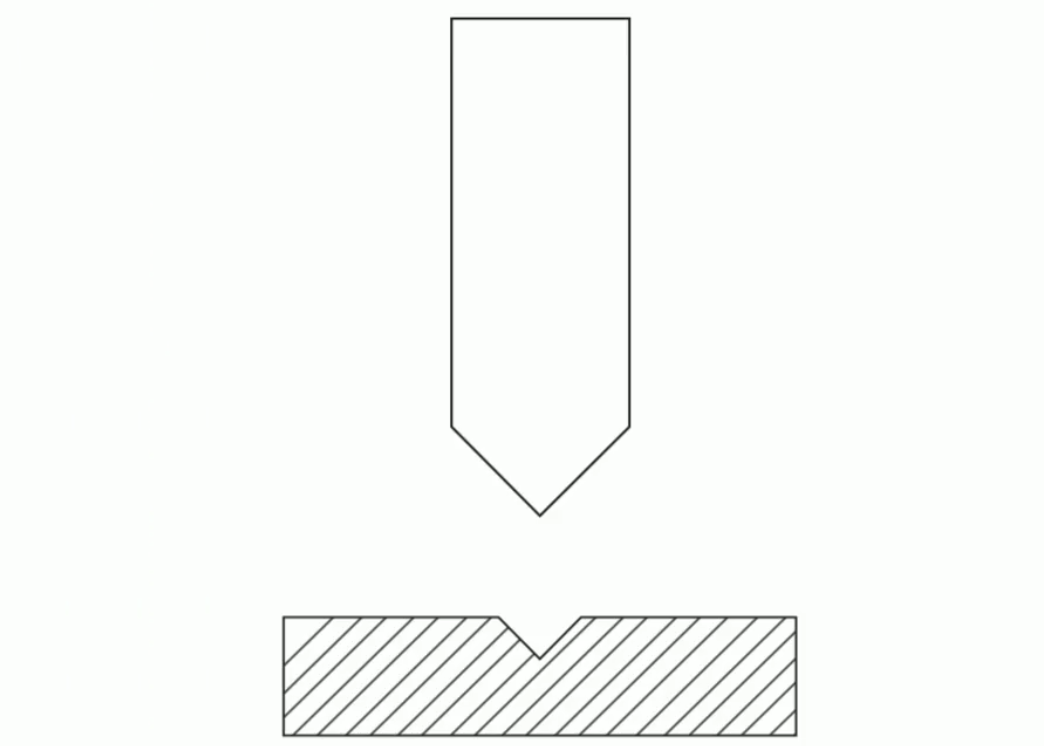

3. Vickers Hardness Tester (HV)

Principle: Use a diamond square pyramid indenter to measure the diagonal length of the indentation to calculate the hardness value.

Features:

High measurement accuracy, suitable for extremely thin or extremely hard materials.

Can measure tiny areas, suitable for hardness testing of coatings, plating or surface hardened layers.

Applicable to samples of various shapes, including samples with arcs (with V-type test bench).

Application scenarios: scientific research laboratories, precision manufacturing industries, and hardness testing of samples with complex shapes.

4. Shore Hardness Tester (HS)

Principle: Use a diamond punch to impact the material surface from a fixed height, measure the rebound height to calculate the hardness value.

Features:

Portable design, suitable for on-site testing.

No need to prepare samples, large workpieces can be measured directly.

The measurement results are greatly affected by the elastic modulus of the material.

Application scenarios: On-site hardness testing of large machinery, steel structures, rubber and other materials.

5. Leeb Hardness Tester (HL)

Principle: The impact body hits the material surface, and the impact velocity and rebound velocity are measured to calculate the hardness value.

Features:

Strong portability, simple operation, suitable for rapid testing of a variety of materials.

Can be converted into Brinell, Rockwell and other hardness values, with wide applicability.

High requirements for sample surface roughness.

Application scenarios: On-site hardness testing in the fields of power, petrochemical, aerospace, etc.

How to choose a suitable hardness tester?

When choosing a hardness tester, the following factors should be considered:

Material properties: Choose a suitable hardness tester according to the hardness range, shape and size of the material.

Measurement accuracy: Vickers hardness tester is recommended for high-precision testing, Rockwell or Leeb hardness tester can be used for rapid testing.

Usage scenario: Benchtop hardness tester is recommended for laboratory testing, and portable hardness tester can be used for on-site testing.

Cost budget: Choose cost-effective equipment according to actual needs and budget.

As one of the few self-developed and self-produced brands in the industry, LABTT has more than 100 hardness testers, ranging from economical and practical ordinary hardness testers to fully automatic high-end intelligent hardness testers, and can provide a series of hardness testing solutions for users.

Summary

Hardness tester is an important tool in the field of material testing. There are many types of hardness testers, each with its own characteristics. Brinell hardness tester is suitable for soft materials, Rockwell hardness tester is suitable for rapid testing, Vickers hardness tester has high accuracy, and Shore and Leeb hardness testers are convenient for on-site use. Choosing a suitable hardness tester can not only improve the efficiency of testing, but also provide reliable guarantee for product quality.

Follow us to learn more about hardness tester knowledge and help you easily cope with material testing challenges!

If you have any questions about the selection or use of hardness tester, please leave a message for consultation!