LATEST NEWS

Press releases & Product news

LABTT Hardness Tester Indenter Replacement Guide

2025-06-03

The hardness tester is a key device for material hardness testing, and the indenter is the core component of the hardness tester. Its status is directly related to the accuracy of the test results. In actual use, the indenter will inevitably wear and crack, so it is particularly important to replace the indenter in a timely manner.

This article will introduce in detail the standard replacement process and precautions for the Vickers hardness tester indenter to help users ensure that the equipment is always in the best working condition. The following content refers to the key points of replacing the indenter of the Vickers hardness tester produced by LABTT.

01 - Necessity of replacing the indenter

Damage to the indenter will directly affect the accuracy of the hardness test, mainly manifested in:

Increased measurement deviation and poor data repeatability

Irregular indentation morphology, affecting measurement readings

Possible damage to the sample surface

Accelerated wear of other parts of the equipment

02 - Standardized replacement process

1. Preparation

Confirm that the power of the equipment is turned off

Prepare a new indenter of appropriate specifications

Prepare special tools (screwdriver)

2. Remove the old indenter

Turn the hand wheel to lower the workbench to the lowest position

Turn the indenter to the front

Mark the connection between the indenter and the spindle

Use a screwdriver to loosen the fixing screw

Carefully remove the old indenter

3. Install the new indenter

Clean the spindle mounting surface

Align the new pressure head with the marked position

Make sure the red dot mark is aligned with the spindle mark

Tighten the top screw

4. Debugging and calibration

Perform indentation test

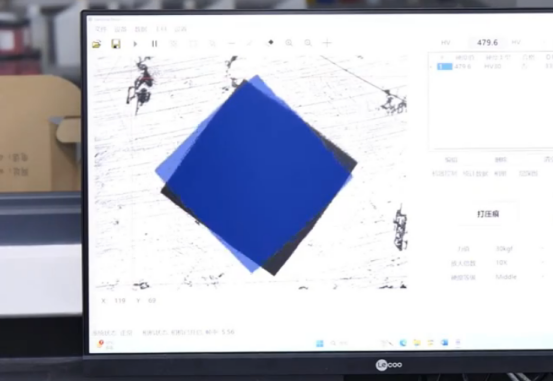

Observe the indentation morphology

If the indentation is not correct, fine-tune the angle of the indenter

Repeat the test until the indentation meets the requirements

Finally, tighten the top screw again

03 - Precautions

Ensure the working environment is clean and prevent dust from entering

Tighten the top screw with moderate force to avoid damaging the thread

Equipment calibration is required after replacement

It is recommended to record the replacement time and indenter batch

04 - Maintenance suggestions

Regularly check the status of the indenter

Establish an indenter usage file

Equip with spare indenters

Perform equipment maintenance regularly

Through standardized indenter replacement operations and daily maintenance, the measurement accuracy of the hardness tester can be ensured and the service life of the equipment can be extended. At the same time, it is recommended that users establish a complete equipment maintenance system and perform regular professional maintenance to ensure the accuracy and reliability of the test data.

If you encounter any problems during the operation, please feel free to contact us and we will provide you with professional technical support.

PREVIOUS: