LATEST NEWS

Press releases & Product news

Highlights of Nanjing Advanced Ceramics Summit Forum: LABTT made a stunning debut with innovative equipment

2025-06-18

From April 11th to 13th, 2025, the Nanjing Advanced Ceramics Summit Forum was grandly opened, attracting nearly a thousand experts, scholars and technical personnel from related companies to actively participate, providing participants with an excellent opportunity to gain an in-depth understanding of industry trends and exchange innovative ideas.

At this exhibition, LABTT made a strong appearance as a technological innovator. Its independently developed product matrix consisting of automatic light-curing cold mounting machines, high-precision micro hardness testers and intelligent cutting equipment won unanimous praise from the experts present, and there was an endless stream of customers consulting on site.

01 Automatic Light-curing Cold Mounting Press

LABTT's LUM-6000S automatic light-curing cold mounting press has a unique low-temperature operation system that ensures a constant sample mounting temperature and provides comprehensive protection for temperature-sensitive materials.

In terms of operational convenience, the LUM-6000S also performs well. The mounting door is equipped with an electric slow-closing device, which runs smoothly and effectively avoids human operating errors. After the mounting process is completed, the door automatically opens and closes, supplemented by sound and light dual prompts, which simplifies the operation process in all directions and greatly improves work efficiency.

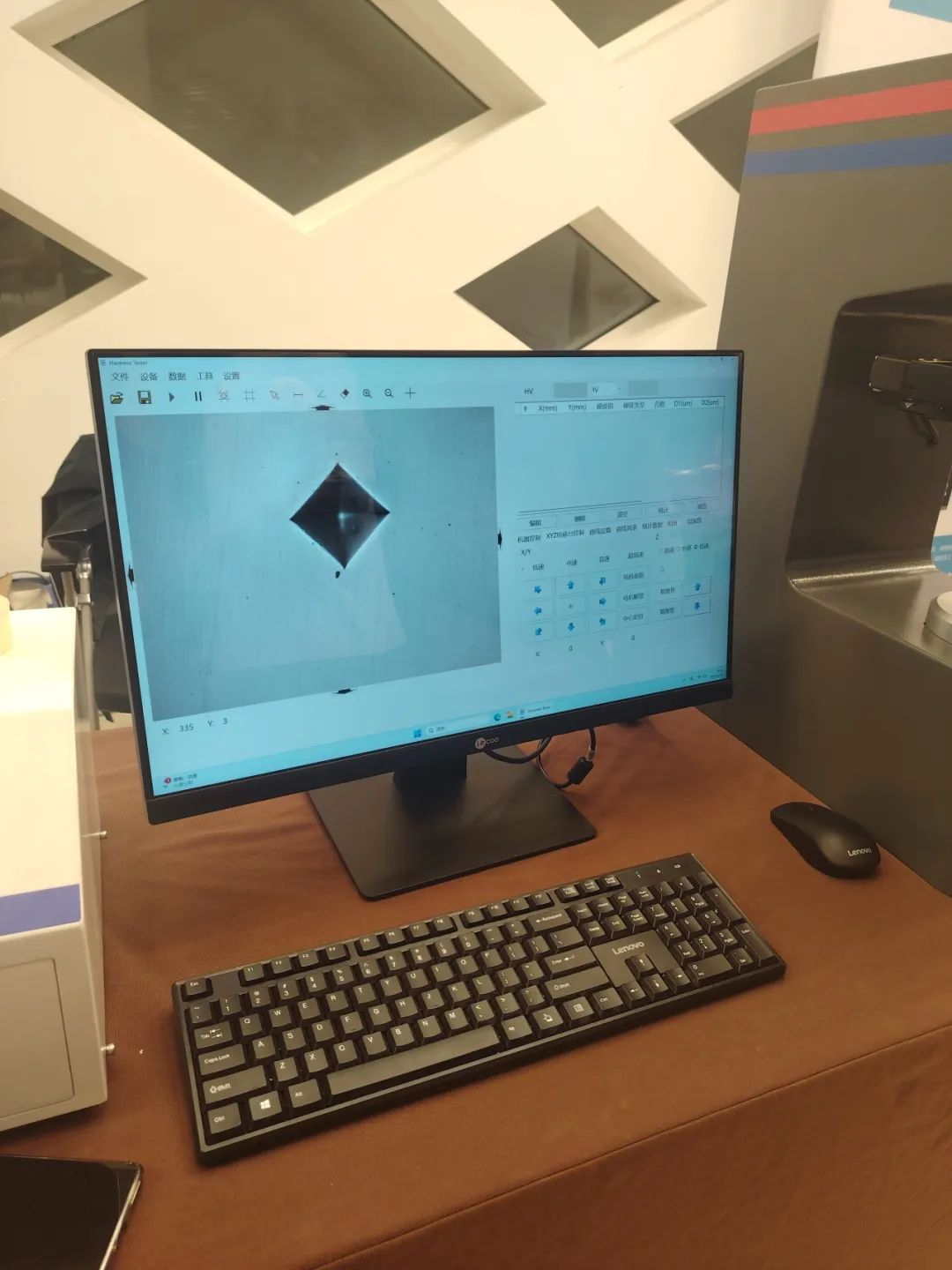

02 Intelligent Micro Vickers Hardness Tester

LABTT intelligent Vickers hardness tester deeply integrates the concept of automation design and demonstrates excellent performance in the field of hardness testing. Its workbench positioning accuracy can reach 1 micron. With this ultra-high precision, it ensures the accuracy of the detection position.

The hardness tester also has a series of intelligent functions, such as automatic focus, automatic adjustment of test force, and automatic measurement, without excessive human intervention. After the test is completed, the test data can be automatically generated and exported in a report, effectively avoiding repeated operations and bringing users a more efficient and convenient testing experience.

03 Precision Cutting Machine

LABTT LC-150 precision cutting combines safety protection and high-precision cutting. The 7 sets of fixtures meet various needs and provide professional sample preparation solutions for various materials. The equipment can achieve precise cutting with 0.01 mm precision lateral movement; through the gravity loading system, the feed speed of the processed object can be accurately adjusted to minimize sample damage.

The LC-150 precision cutting machine has a high degree of automation. When the sample cutting is completed, the cutting machine can stop automatically, which can realize unattended processing and effectively optimize the workflow.

In this exhibition, LABTT not only received a large number of potential customers' orders, but also reached cooperation consensus with many industry authorities, successfully expanded the market territory, and added a strong stroke to the Nanjing Ceramics Exhibition.