LATEST NEWS

Press releases & Product news

Aluminum Alloy Specimen Cutting: Pain Points and Solutions

2025-06-18

Aluminum alloy is a material that is often encountered during the cutting process, but this material is not easy to cut. Today, we will take a deep look at the pain points in aluminum alloy specimen cutting and present an effective solution for you.

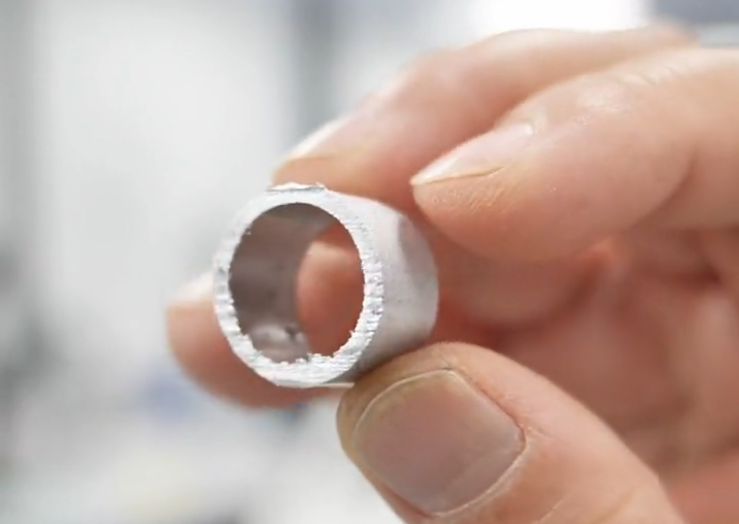

1. Edge deformation and burr problems

During cutting, the edge of the sample is easily deformed and accompanied by burrs. This not only affects the appearance of the sample, but also seriously interferes with the subsequent metallographic observation, causing deviations in the observation results.

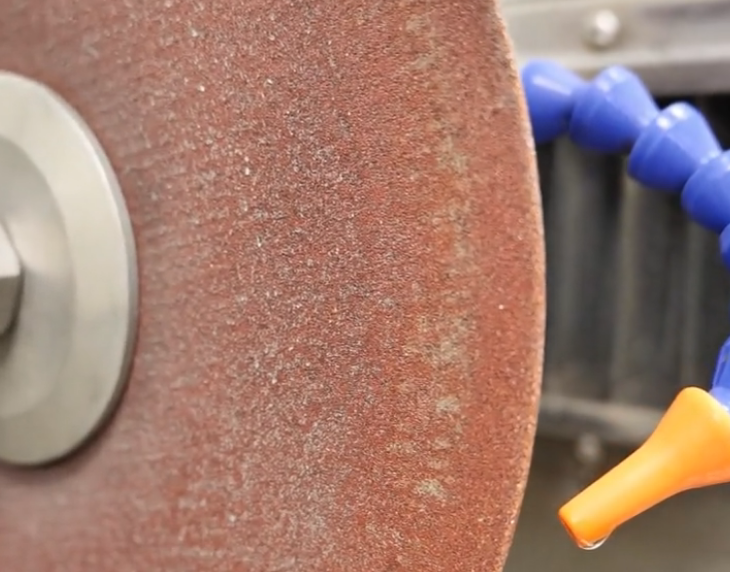

2. Aluminum shavings adhere to the cutting disc

Aluminum shavings are very easy to adhere to the surface of the cutting disc. This not only reduces the cutting efficiency, but once the cutting disc is blocked, the cutting work will come to a standstill, and even cause the cutting disc to be damaged, increasing costs.

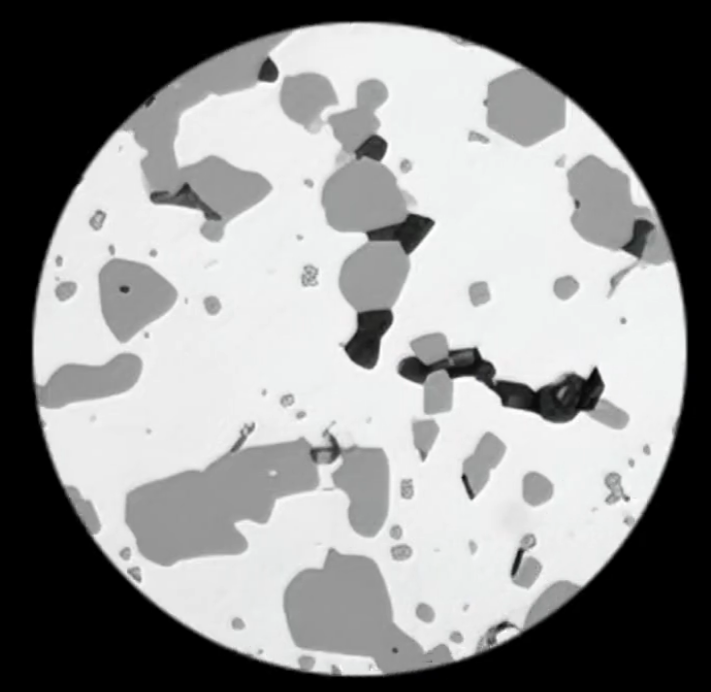

3. Local high temperature triggers microstructure phase change

The melting point of aluminum alloy is relatively low, about 660℃. The local high temperature generated during the cutting process is very likely to trigger microstructure phase change, such as overburning, which directly destroys the original metallographic structure and makes the previous preparations go to waste.

4. The oxide layer conceals the true structure

High temperature causes the surface of the aluminum alloy sample to oxidize rapidly, forming an aluminum oxide layer. If the subsequent grinding method is improper, this oxide layer will conceal the true structure and mislead the research and test results.

One-stop solution

1. Equipment upgrade

The automatic metallographic precision cutting machine is selected, and its excellent stability is a strong guarantee for cutting accuracy. Compared with traditional equipment, it can effectively reduce vibration during the cutting process and reduce the risk of sample deformation from the root. LABTT provides a full range of precision cutting equipment, covering a variety of cutting needs from conventional to difficult samples.

2. Cutting disc selection

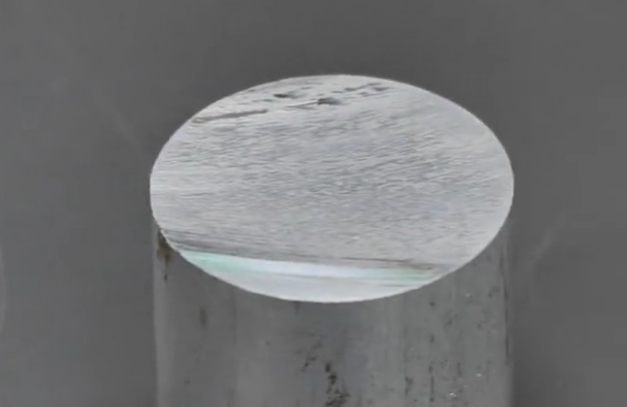

For users who pursue high precision, diamond cutting disc is the best choice. Its ultra-high hardness and wear resistance can ensure a stable cutting process and a smooth and flat cutting surface.

If you pay more attention to economy and anti-sticking properties, resin cutting disc is the ideal choice. It can not only cut efficiently, but also effectively prevent aluminum chips from adhering, extending the service life of the cutting disc. Similarly, LABTT produces these two cutting discs, with multiple models available, which are ideal for material cutting.

3. Coolant Uses Water-based coolant is used and continuously sprayed on the cutting area. The professional coolant produced by LABTT can not only quickly reduce the cutting temperature, prevent tissue phase change and surface oxidation, but also wash away the aluminum chips in time to keep the cutting area clean.

4. Cutting process optimization

Choose low-speed cutting to reduce the generation of frictional heat. At the same time, feed slowly and evenly, and it is best to cut along the length of the sample, which can reduce the cross-sectional area, reduce heat accumulation, and protect the original metallographic structure of the sample to the greatest extent.

Although there are many difficulties in cutting aluminum alloy samples, as long as the right methods and equipment are selected, these problems can be solved. I hope that the content shared today can provide you with powerful help in the cutting of aluminum alloy samples.