LATEST NEWS

Press releases & Product news

LABTT presents cutting-edge solutions at the Control Expo in Germany, jointly drawing a picture of the future of quality inspection

2025-06-18

From May 6 to 8, 2025, the Stuttgart Quality Control Exhibition in Germany opened grandly, where the world's top companies and technical elites gathered to explore the cutting-edge trends in the field of quality control. As a leading company in the industry, LABTT made a stunning appearance with its star products, leaving a strong mark at this international event with its innovative technology and excellent quality.

The exhibition site was crowded with people, and the LABTT No. 3310-3 booth became one of the focuses of the whole venue. Participants were attracted by the cutting-edge products exhibited by LABTT, such as the intelligent Rockwell hardness tester, micro Vickers hardness tester, and fully automatic metallographic grinding and polishing machine, and the atmosphere of communication in front of the booth was always hot.

01 iHR Intelligent Rockwell Hardness Tester

LABTT, a new generation of intelligent products, allows measurement to be completed instantly with the simple operation of "one-click". Equipped with a fully automatic high-precision force sensor and a closed-loop force feedback control system, it ensures that every data collection is accurate and correct.

The automatic lifting function of the workbench, combined with the anti-collision detection device and the Z-axis retraction system, greatly improves efficiency while ensuring the safe operation of the equipment. Its repeated positioning accuracy is 3 microns, and the maximum stroke can reach 200mm, which can easily meet different hardness testing needs.

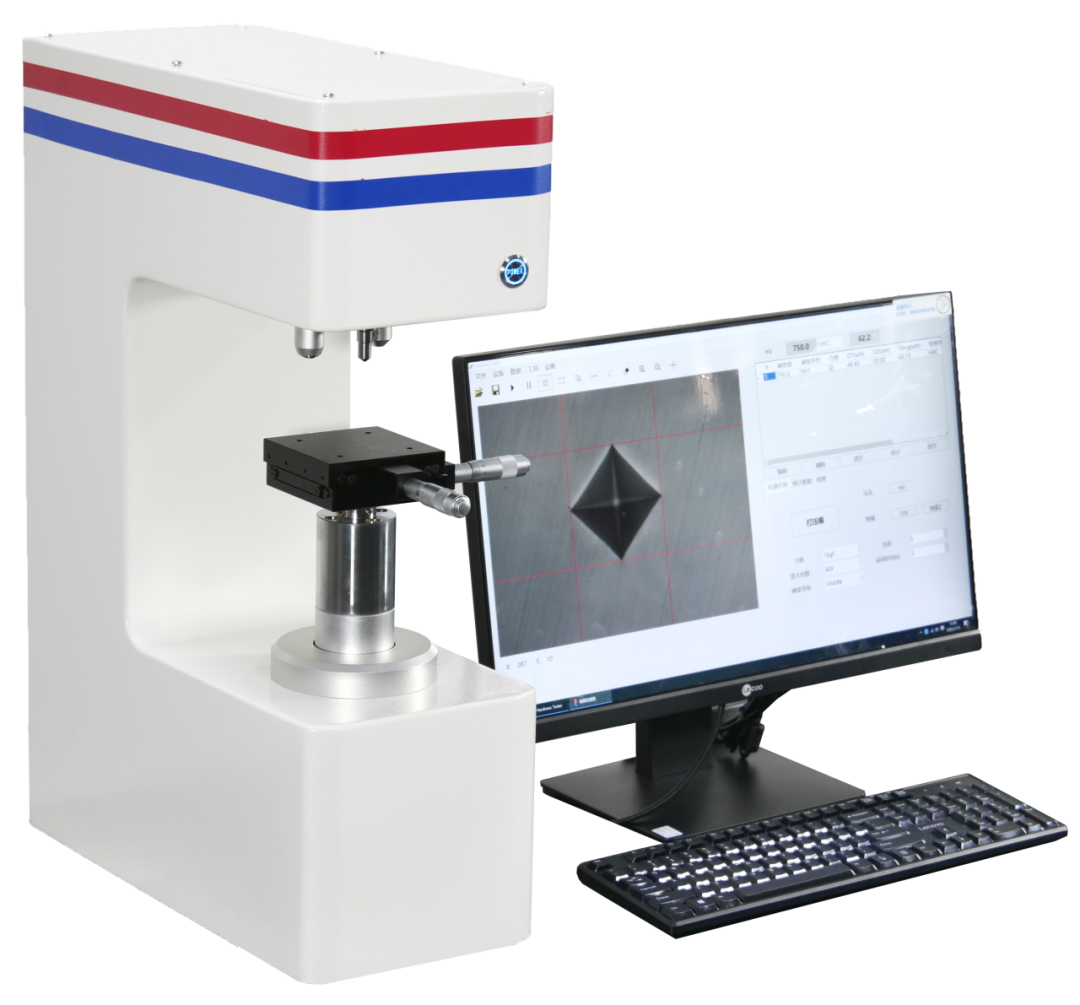

02 Micro Vickers Hardness Tester

The THV-1MPE micro hardness tester exhibited this time is also a popular product of Naibo. The integrated minimalist design takes into account both beauty and practicality. The built-in 5 million high-definition camera can clearly capture the subtle structure. At the same time, the equipment is equipped with a brand computer and special software as standard, which enables data processing and analysis to be completed with one click.

The unique optical cross-guide lifting system ensures that the indentation is accurately focused and the image position is stable when the sample is lifted and lowered, providing reliable guarantee for hardness measurement.

03 Fully automatic metallographic grinding and polishing machine

This grinding and polishing machine adopts a central loading force design, fixes six samples at a time, and completes the grinding and polishing automatically throughout the process, ensuring that each sample presents a complete plane, greatly improving the grinding and polishing efficiency. The grinding and polishing disc and the sample disc are independently controllable, and various parameters such as speed and grinding and polishing time can be adjusted at will to meet the needs of various experiments.

Equipped with an intuitive touch screen interface, the operation is simple and smooth. The equipment is known for its high precision, low noise, and stable operation. It can create a quiet and efficient working environment for the laboratory and is an ideal choice for scientific research and production.

At the exhibition that just concluded, LABTT demonstrated its professionalism with its excellent product performance and cutting-edge innovative technology, and received high attention and recognition from many participants. In the future, LABTT will continue to deepen its presence in overseas markets, with technological innovation as the core, to provide international customers with more efficient and reliable testing equipment and services.