LATEST NEWS

Press releases & Product news

A must-have for the laboratory! Take you to know the metallographic cutting disc in 1 minute

2025-06-19

Metallographic cutting discs (also known as metallographic grinding wheels) are special tools used to cut specimens in metallographic sample preparation. They are designed to obtain flat, damage-free sample cross-sections through precise cutting, providing a basis for subsequent microscopic observations (such as metallographic microscopes and scanning electron microscopes).

Differences from ordinary cutting discs:

Thinner thickness: The thickness of metallographic cutting discs is usually 1.5-2mm (ordinary grinding wheel discs are 3.2-3.8mm), which reduces material deformation caused by cutting stress.

Better elasticity: High resin content can buffer the feed load and reduce the risk of plastic deformation of samples.

Less thermal damage: Special abrasives (such as diamond, silicon carbide) are sharp and generate less heat, protecting the sample microstructure

Main types:

Resin-based: good elasticity, smooth cutting surface, suitable for soft metals (aluminum, copper) or precision cutting.

Metal-based (sintered): strong wear resistance, suitable for hard materials (such as ceramics, cemented carbide), long service life.

Nickel-based (electroplating): fast cutting speed, low cost, but short life, suitable for rapid material removal.

Applicable material range:

Metals: stainless steel, cast iron, hardened steel, aluminum alloy, titanium alloy, etc.

Non-metals: ceramics, silicon wafers, quartz, plastics, composite materials.

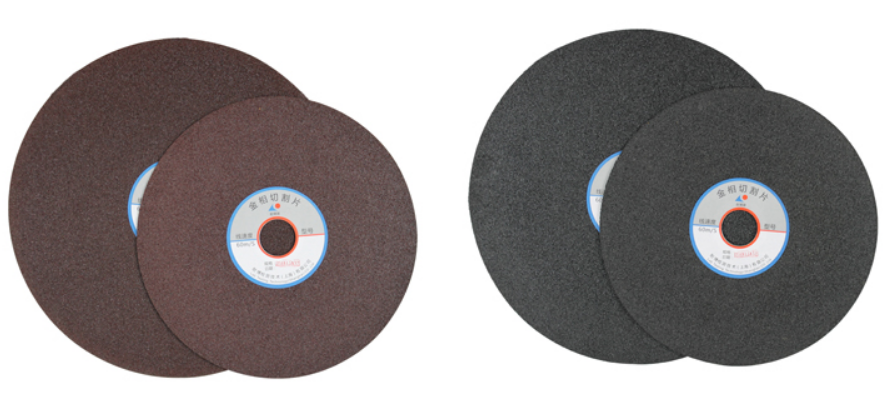

LABTT has developed a series of metallographic cutting discs that are specially used for metallographic sampling according to the different materials of metallographic samples. They are available in a variety of specifications and are suitable for metallographic sample cutting machines of various models and specifications at home and abroad.