LATEST NEWS

Press releases & Product news

Innovation drives the future with intelligence—LABTT shines at the 15th Shanghai Fastener Exhibition

2025-06-23

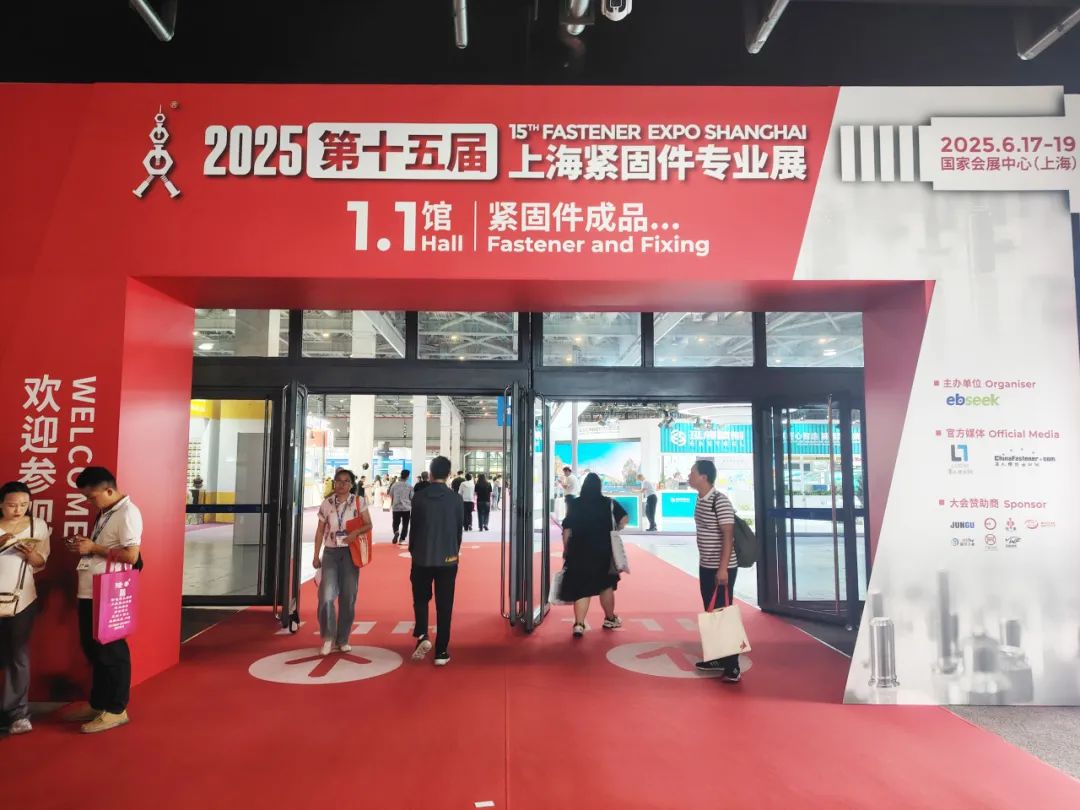

The 15th Shanghai Fastener Exhibition was held from June 17 to 19. The exhibition brought together many top companies and suppliers, and fully presented the latest breakthroughs in the intelligent and green development of the fastener industry.

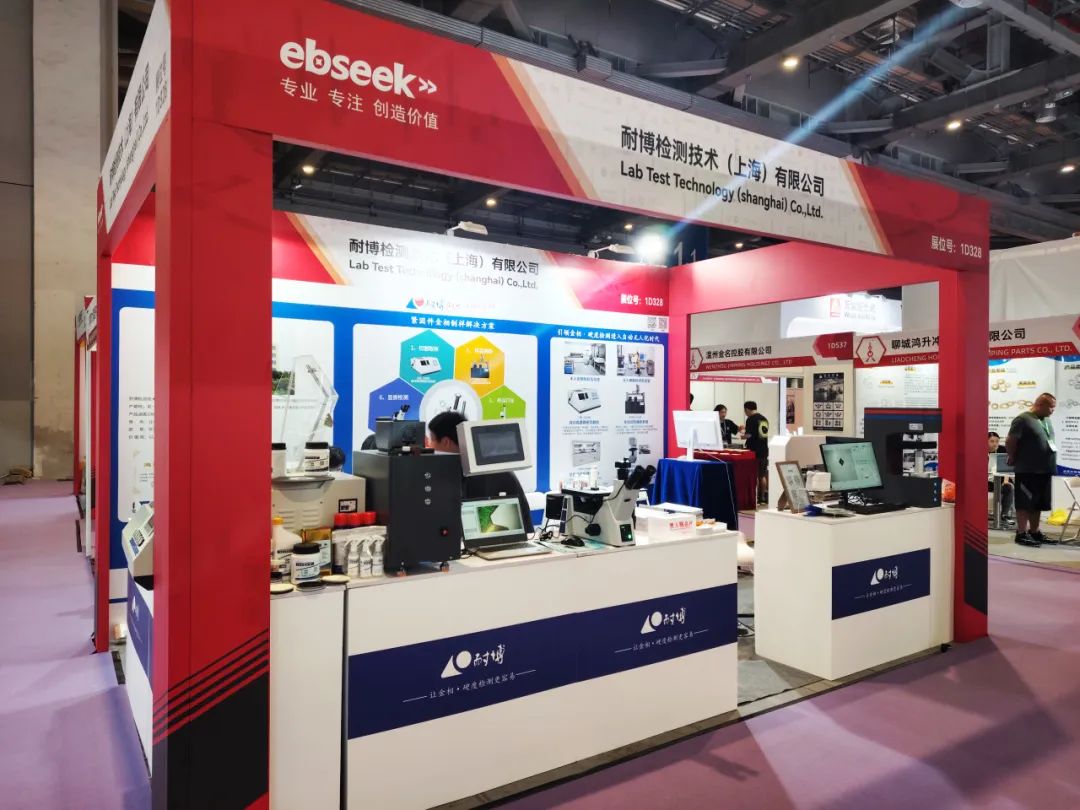

At the exhibition, LABTT fully demonstrated its independently developed metallographic and hardness testing equipment, covering five key links: precision cutting, intelligent inlaying, efficient grinding and polishing, accurate hardness testing and high-precision microscopic analysis, providing full-process quality assurance for fastener manufacturing and helping companies achieve more efficient and accurate quality control.

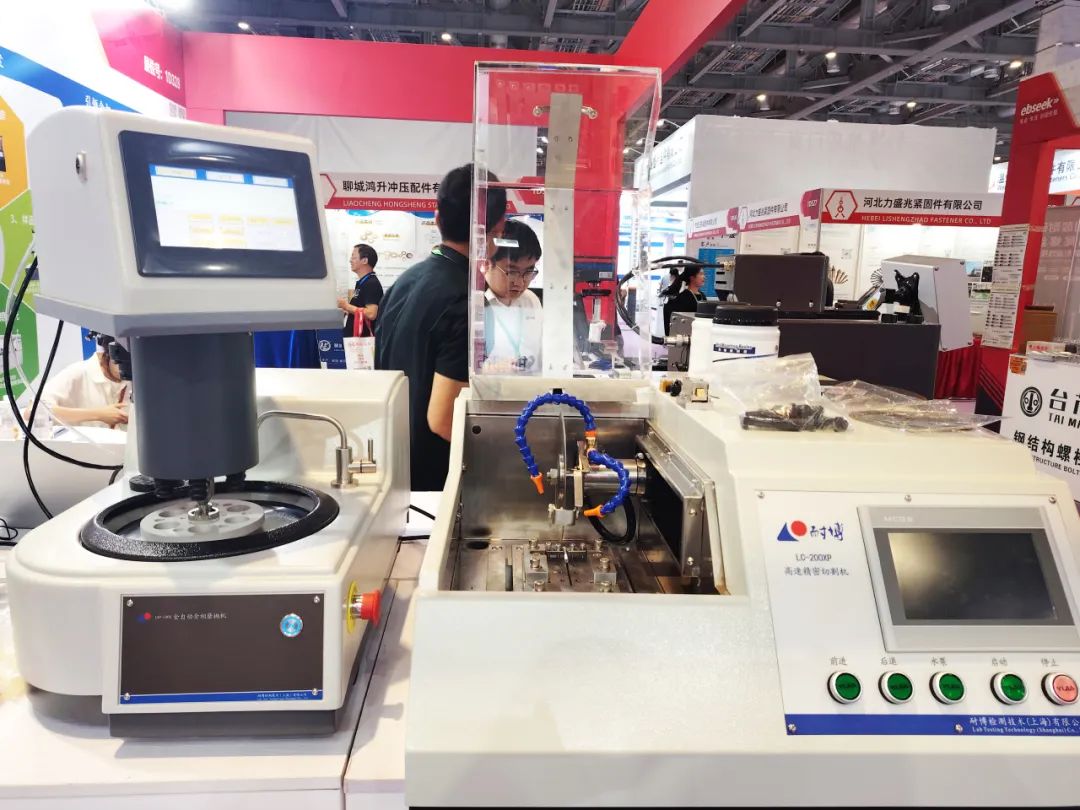

Automatic High-speed Precision Cutting Machine

The LC-200XP automatic high-speed precision cutting machine exhibited this time innovatively adopts Y-axis automatic feeding technology, standard X-axis translation function, and optional R-axis rotation module and double-blade cutting system. This equipment supports a variety of customized configuration solutions, and can be accurately adapted to different material characteristics to ensure high-efficiency and high-precision cutting processing.

Fully Automatic Hot Mounting Press

The iHM-4000 fully automatic hot mounting press developed and produced by LABTT can start the full process of automated operation with one button: automatic mold closing, precise pressurization, intelligent temperature control, rapid cooling, automatic demoulding, and realize unattended and efficient mounting. The equipment has 99 sets of process storage built in to meet the needs of diverse samples. At the same time, it can be upgraded to multi-station and automatic quantitative addition of mounting material configuration.

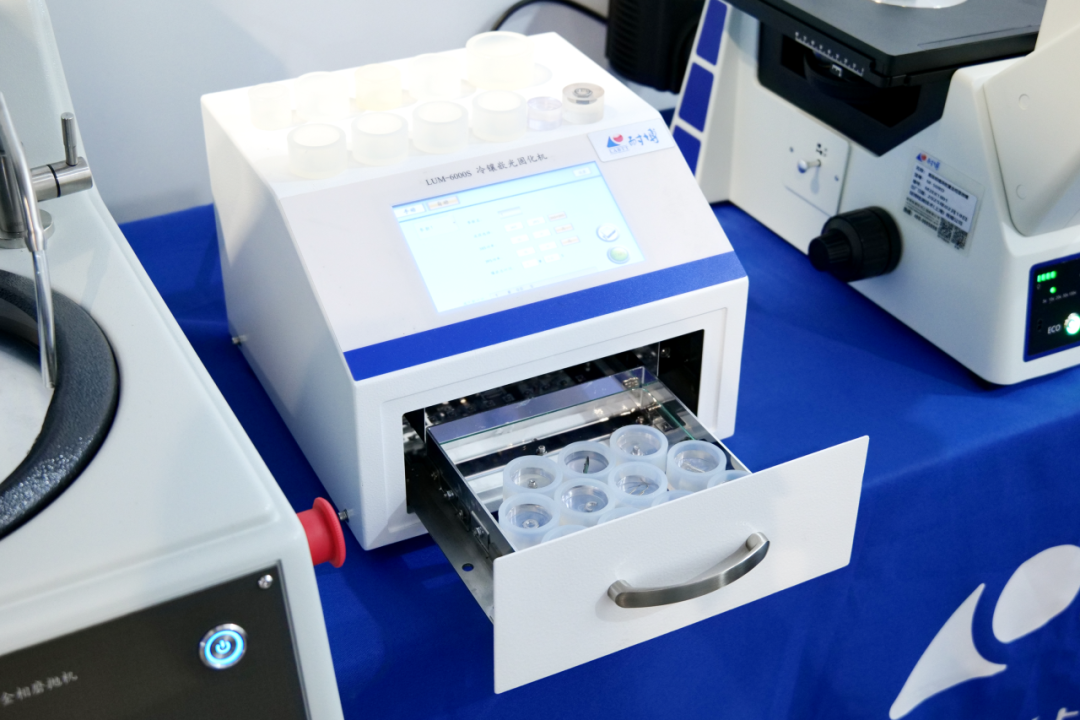

Automatic Light-curing Cold Mounting Press

The LUM-6000S automatic light-curing cold mounting press on display provides a perfect mounting solution for temperature-sensitive materials with its innovative low-temperature light-curing technology, effectively avoiding the risk of thermal damage to sensitive samples caused by traditional hot mounting and ensuring the integrity of the sample's microstructure.

Fully Automatic Metallographic Grinding and Polishing Machine

LAP-1000 fully automatic metallographic grinding and polishing machine, the equipment adopts a central loading force design. Six samples can be fixed at one time during grinding and polishing, and processed simultaneously to ensure that each sample presents a complete plane, meeting the needs of large-scale fastener testing, and significantly improving work efficiency. The grinding and polishing disc and the sample disc are independently controllable, and all parameters from speed to grinding and polishing time can be freely adjusted.

Metallographic Microscope

LABTT M-50BD metallographic microscope adopts infinite optical system, equipped with 360° rotating binocular observation tube and low hand position operation design, suitable for long-term use. It supports multiple observation methods such as bright field, dark field, polarization, differential interference, etc., and is widely used in metal material detection, heat treatment research and industrial analysis.

Fully Automatic Vickers Hardness Tester

The iHV-1AZXY intelligent Vickers hardness tester launched this time, relying on self-developed intelligent software, can achieve fast and accurate focusing without manual positioning. With the support of innovative algorithms, even facing complex surfaces with roughness or scratches, it can accurately complete indentation detection. The equipment supports automatic switching of experimental force values, intelligent adjustment of brightness and contrast, further improving detection efficiency and accuracy.

Bolt Rockwell Hardness Tester

LABTT launched the THR-150DX-Z Bolt Hardness Tester at this fastener exhibition. This is a high-precision testing equipment developed specifically for the fastener industry. Its innovative bolt-specific fixture design can be flexibly adapted to a variety of specifications, ensuring the stability and reliability of the testing process while ensuring the high accuracy of the test data. The device uses an intelligent one-button operating system, which can quickly complete the fastener hardness measurement and significantly improve the testing efficiency. It is an ideal choice for the fastener production quality control link.

LABTT relies on its self-developed metallographic and hardness professional testing equipment to provide a full range of quality control solutions for the fastener industry. Looking ahead, LABTT will continue to increase R&D investment, deepen technological innovation, and develop collaboratively with industry partners to jointly promote the transformation and upgrading of the fastener industry towards high precision and intelligence.

PREVIOUS: