LATEST NEWS

Press releases & Product news

LABTT fully automatic hot mounting system makes sample preparation easier

2025-06-30

One-click start, multiple samples can be mounted simultaneously! LABTT fully automatic hot mounting system makes sample preparation easier

Are you still worried about the low efficiency of sample mounting? The traditional hot mounting process requires manual loading, repeated parameter adjustment, and long waiting for cooling... It is not only time-consuming and labor-intensive, but also easy to cause sample deformation or scrapping due to operational errors. Especially when facing the need to process large quantities of samples, the experimental progress is seriously delayed.

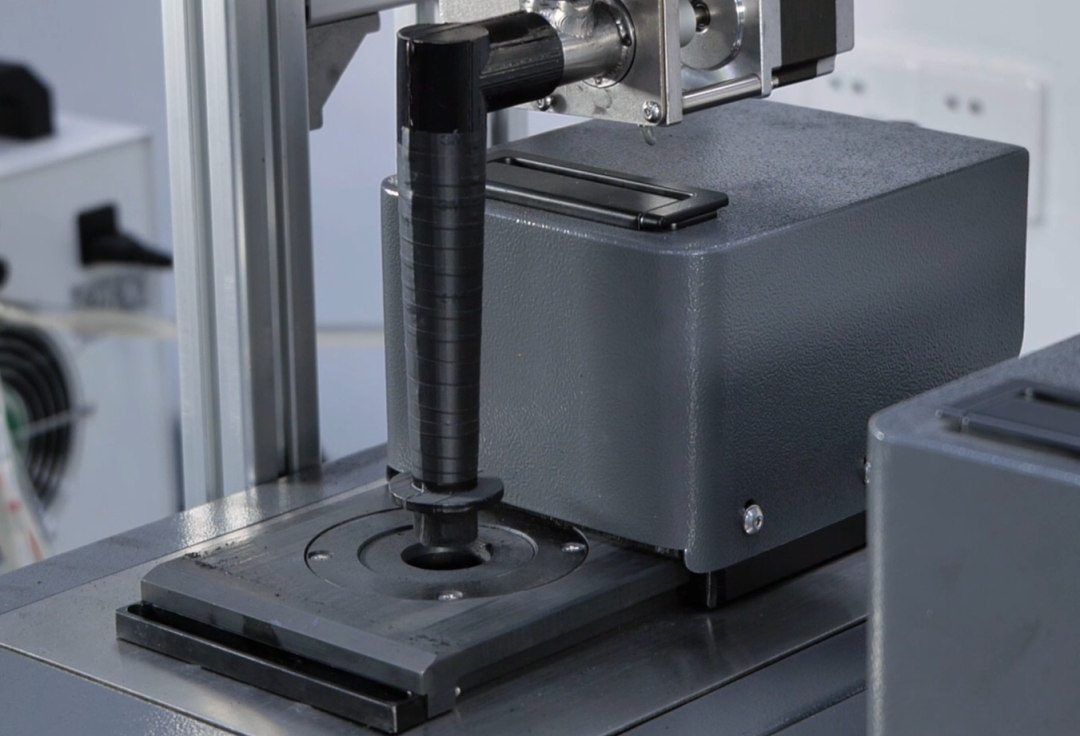

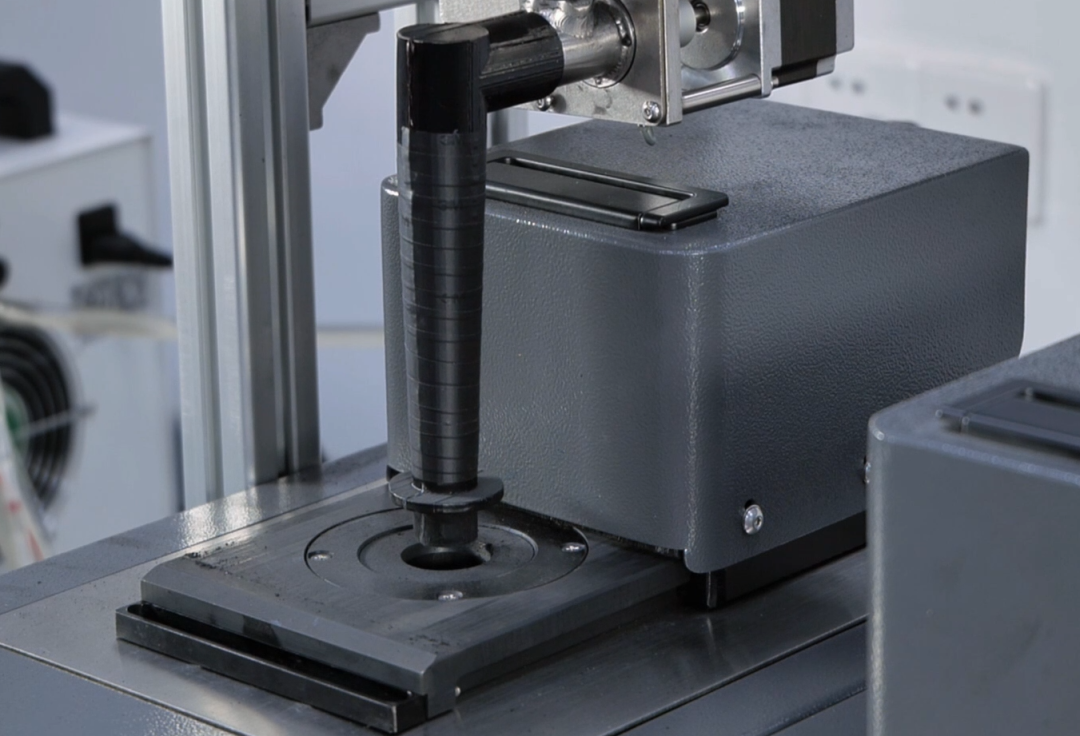

The demand for efficient batch mounting has become an urgent problem to be solved in most laboratories. For this reason, the iHMS-6000 fully automatic hot mounting system independently developed by LABTT came into being. With one-click start, multiple samples can be accurately mounted at the same time, greatly improving efficiency.

Multi-station parallel processing doubles production capacity

One of the biggest highlights of the iHMS-6000 fully automatic hot mounting system is that it can achieve simultaneous mounting of multiple samples. The equipment can be freely combined with dual or multi-stations, and a single run can complete three times the workload of traditional equipment.

At the same time, the entire process is automated, from loading, pressurizing, heating, cooling to ejecting samples, without manual intervention, and 24-hour continuous production without pressure.

Process storage, precise matching

The built-in 99 sets of inlay process storage function is even more eye-catching. Whether it is common metal materials or special composite materials, we can find suitable inlay processes in the system, and novices can also easily get started.

Just select the corresponding process, and the system can automatically adjust the parameters to ensure that each inlay can achieve the best effect.

Pre-pressing function protects samples

In order to prevent samples from being deformed or crushed during the mounting process, iHMS-6000 has a built-in pre-pressing function. We can freely set the pre-pressing pressure, temperature and time according to the characteristics and requirements of the sample to provide all-round protection for the sample.

Automatic addition, precise control

The automatic and quantitative addition component of the inlay material is a thoughtful design of the iHMS-6000. It can automatically add inlay materials in a quantitative manner, and the amount of addition can be set and automatically controlled according to our needs. In this way, it not only avoids the inaccuracy and waste of manual addition, but also improves the quality of inlay.

Optional automation components to create an "unmanned laboratory"

The sample moving component adds a touch of intelligence to the iHMS-6000. The intelligent robotic arm can automatically grab the sample before mounting and place it in the mounting mold. After the mounting is completed, it can automatically grab the sample and place it in the designated position. The whole process does not require human intervention, and truly realizes fully automated operation.

If you are also worried about the low efficiency of sample mounting, you might as well try the iHMS-6000 fully automatic hot mounting system. It will bring you a more relaxed and efficient mounting experience with its powerful functions!