LATEST NEWS

Press releases & Product news

A new height in material testing! LABTT shines at China Materials Conference 2025

2025-07-11

From July 5 to 8, the China Materials Conference 2025 and the New Materials Scientific Research Instruments and Equipment Exhibition were grandly opened at the Xiamen International Convention and Exhibition Center. As a national academic event in the field of new materials, the conference brought together top experts, cutting-edge technologies and high-end equipment to explore industry breakthroughs and innovative futures. LABTT participated deeply in the conference, demonstrated its innovative achievements and technical strength, and won high attention from industry authorities.

At the exhibition, LABTT fully demonstrated its self-developed and self-produced metallographic and hardness testing equipment, providing a full set of solutions from cutting, mounting, grinding and polishing, hardness testing to microscopic analysis, realizing the intelligent upgrade of the entire process of material analysis, and providing more efficient and accurate quality control guarantees for material research and industrial applications.

Precision Cutting Machine

LABTT LC-150 cutting machine, equipped with a closed transparent protective cover and intelligent safety switch, is safe and visible to operate. The equipment uses a 0.4mm ultra-thin diamond cutting blade, and lateral movement can achieve micron-level precision cutting. It comes standard with 7 professional fixtures and an optional large-size cutting table, which can easily cope with the sample preparation needs of various hard and brittle materials from circuit boards to rocks.

Precision Grinding and Polishing Machine

LABTT's LAP-100U precision grinding and polishing machine has become the focus of the audience with its excellent processing accuracy and stable process performance. This professional equipment can achieve high-precision surface treatment through innovative grinding and polishing technology, significantly improve the flatness and finish of materials, and provide key process guarantees for high-end material manufacturing.

Intelligent Fully Automatic Brinell Hardness Tester

The iHBRV-250 intelligent fully automatic Brinell hardness tester integrates three hardness tests: Brinell, Rockwell and Vickers. With ultra-high precision electric X/Y worktable and intelligent positioning system, it can achieve zero deviation in measurement. The new generation of electric traverse table can automatically switch between pressure measurement and measurement. With professional measurement software, one-click operation can produce accurate results in seconds, making complex hardness testing simple and efficient.

Fully Automatic Vickers Hardness Tester

The intelligent Vickers hardness tester on display, relying on self-developed intelligent software, can achieve fast and accurate focusing without manual positioning. With the support of innovative algorithms, it can accurately complete indentation detection even on complex surfaces that are not smooth or have scratches. The equipment supports automatic switching of experimental force values, intelligent adjustment of brightness and contrast, further improving detection efficiency and accuracy.

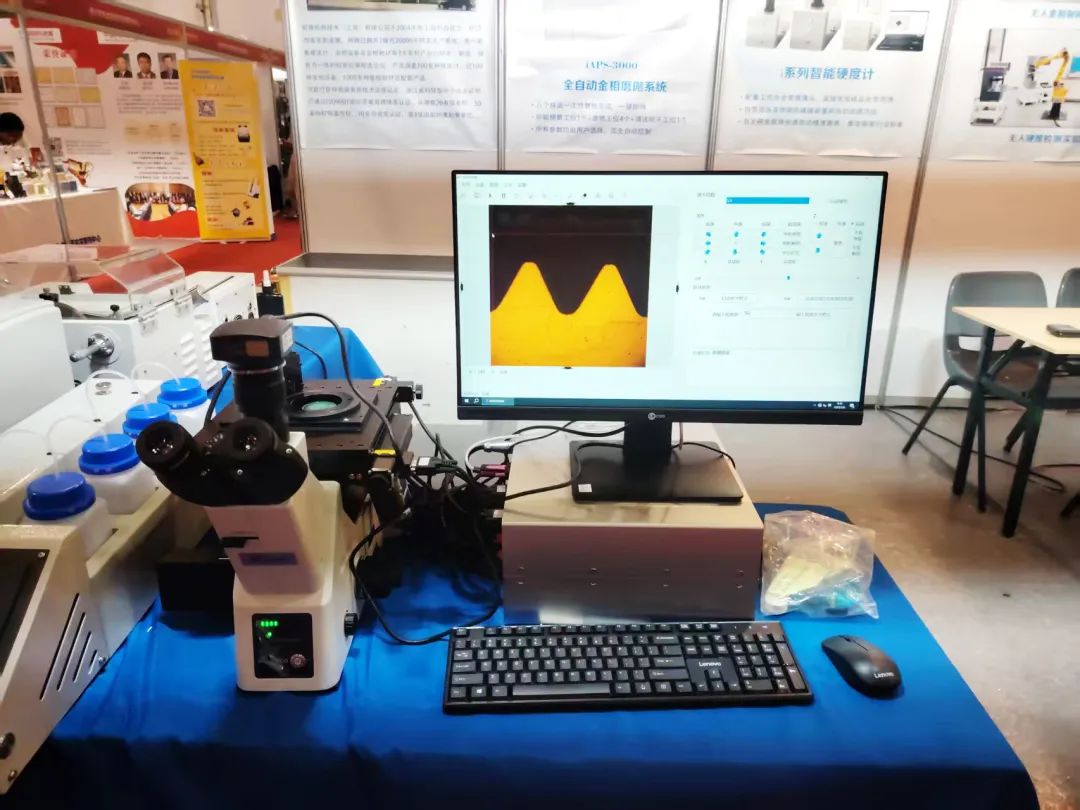

Metallographic Microscope

The metallographic microscope exhibited by LABTT this time adopts an infinite optical system, equipped with a 360° rotating binocular observation tube and a low-hand operation design, suitable for long-term use. It supports multiple observation methods such as bright field, dark field, polarization, differential interference, etc., and is widely used in metal material testing, heat treatment research and industrial analysis.

At the China Materials Conference 2025, LABTT demonstrated the innovative strength of domestic high-end instruments with a complete material testing solution. These achievements not only demonstrate LABTT's technical accumulation in the field of precision instruments, but also provide solid technical support for the high-quality development of the new materials industry.

In the future, LABTT will continue to deepen its roots in the field of material testing, drive development with innovation, and contribute to material science research.