LATEST NEWS

Press releases & Product news

How can a tiny screw support a 10,000-ton bridge? Metallographic analysis reveals its hidden genetic code.

2025-09-22

It's only one-third the size of a thumb, yet it supports a 10,000-ton bridge; it silently guards every takeoff and landing of an airplane. Today, let's use metallographic examination technology to uncover the microscopic secrets of this tiny screw!

Step 1: Precision Sample Preparation

Due to the screw's tiny size, we used a LABTT precision cutting machine to section along its axis to prevent high temperatures from altering the material structure. After sectioning, the sample was mounted and secured for the next grinding and polishing steps.

Using a LABTT semi-automatic grinding and polishing machine, we polished the screw in steps from 180# to 800# water-treated sandpaper, followed by precision polishing with 5μm and 1μm diamond spray polishers. Each step is designed to perfectly reveal the material's true appearance.

Step 2: Solving the Corrosion Problem

The screw's surface is shiny, and we can't determine whether it's stainless steel or plated medium-carbon steel. First, a corrosion test was conducted using a 4% nitric acid solution. The sample surface quickly turned gray, demonstrating the effectiveness of the corrosion agent. The sample was then rinsed with water, sprayed with alcohol, and quickly dried, preparing for microscopic examination.

Step 3: Microscopic Observation

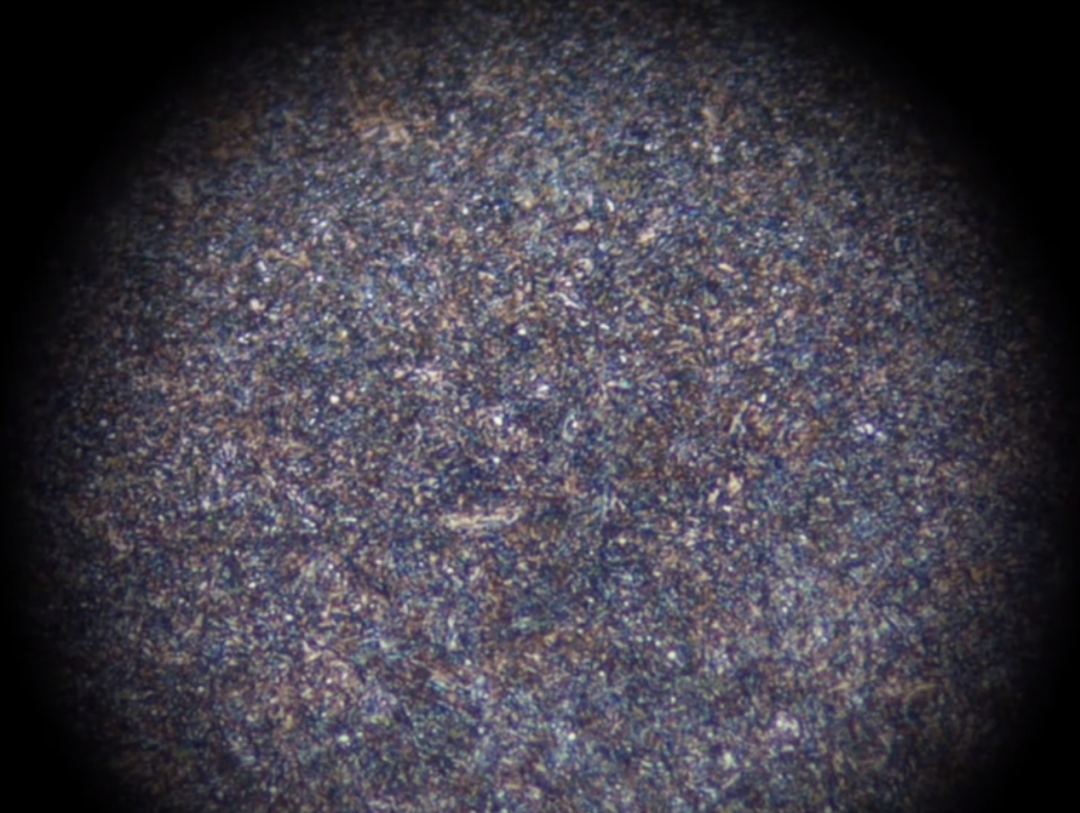

Finally, the corroded sample was placed under a LABTTs metallographic microscope for observation. At 100x magnification, the matrix structure was delicate and difficult to discern; however, at 500x magnification, the material's structure was clearly tempered bainite with fine carbide particles—a typical quenched and tempered structure of medium-carbon steel!

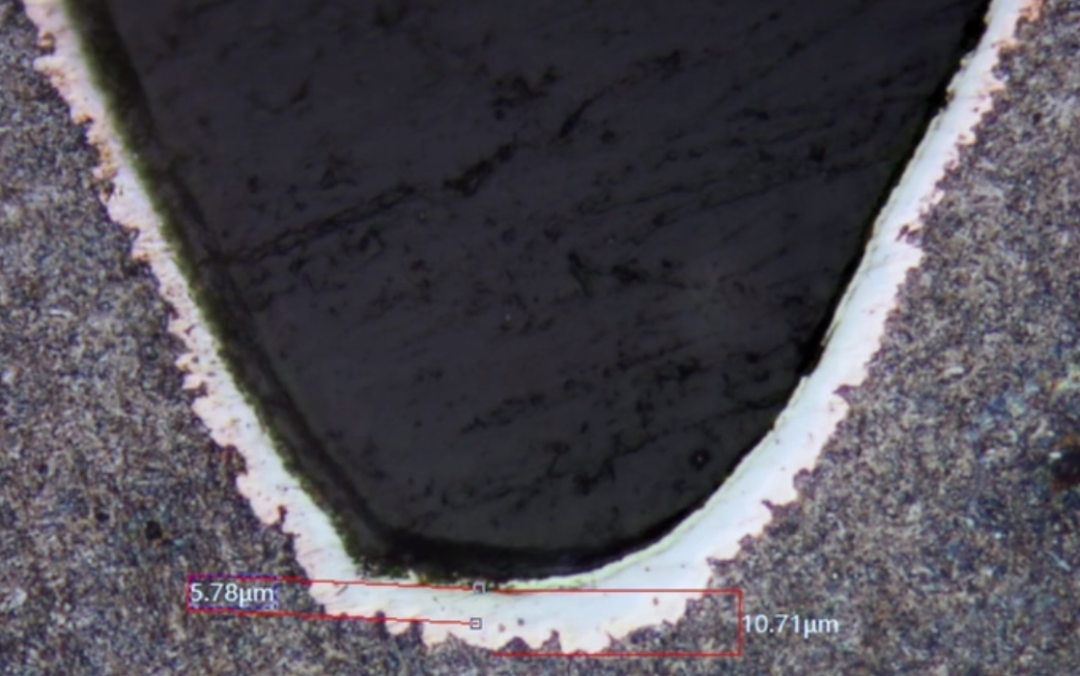

Observing the thread, judging by the color of the surface coating, the coating consists of two layers, totaling 11 microns. The topmost layer is likely chromium, measuring 6 microns thick; the second, orange-red layer is copper, representing functional copper plating. No defects were observed throughout the coating, but the thickness of the coating varied across different parts of the screw, indicating poor uniformity of the electroplating.

Step 4: Professional Summary

This screw is made of quenched and tempered medium-carbon steel with chrome and copper plating, not stainless steel. The copper layer serves as a base layer, enhancing bonding strength and corrosion resistance, while the chromium layer primarily provides a decorative luster and some corrosion resistance. Based on metallographic observations, this screw is suitable for medium loads and applications requiring decorative surfaces, but is not recommended for use in environments requiring high corrosion resistance.

A seemingly ordinary screw embodies the wisdom of materials science, electroplating processes, and precision testing. Every tiny industrial component has its own unique "genetic code," waiting to be discovered and deciphered.

PREVIOUS: