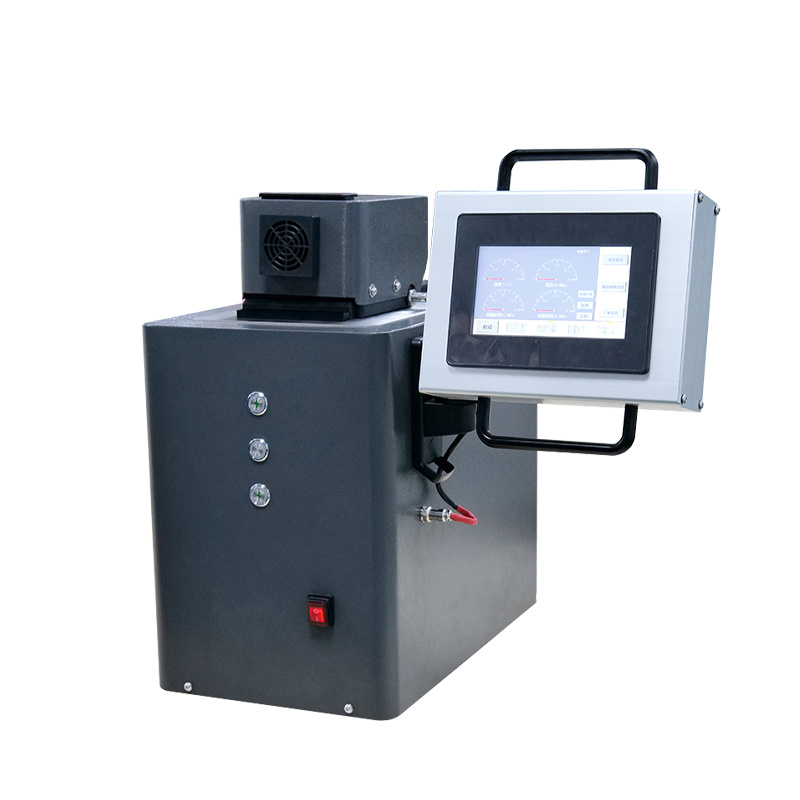

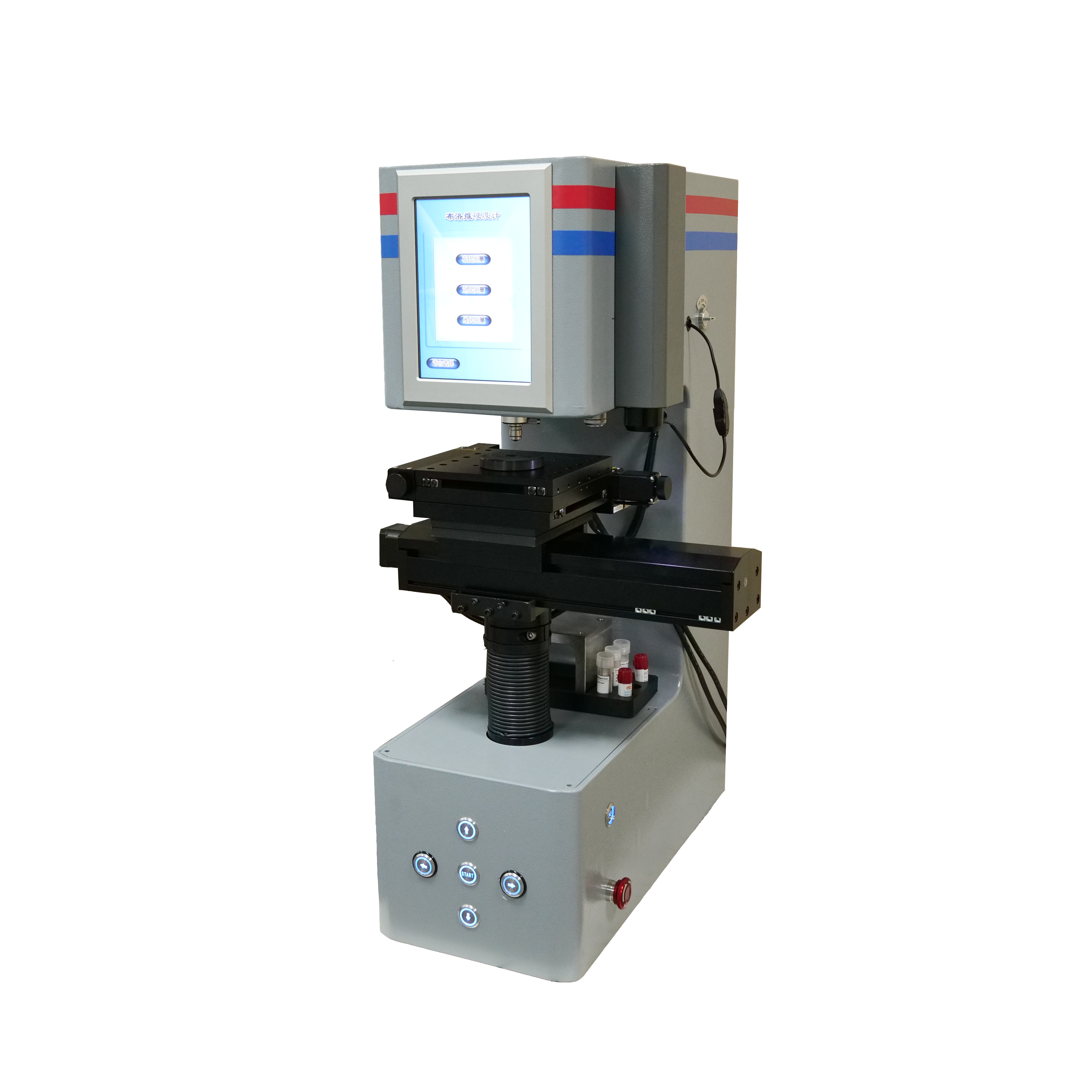

Automatic High Speed Precision Cut-off Machine

iMC-250

PRODUCT ADVANTAGES

The spindle adopts servo control, high speed, stepless speed regulation, overload protection.

Innovative Y-axis intelligent cutting method, automatically and quickly finds the cutting starting point, automatically adjusts the cutting speed according to the load, and automatically ends the cutting when the cutting is completed.

Traditional Y-axis manual, automatic, impact and other cutting methods.

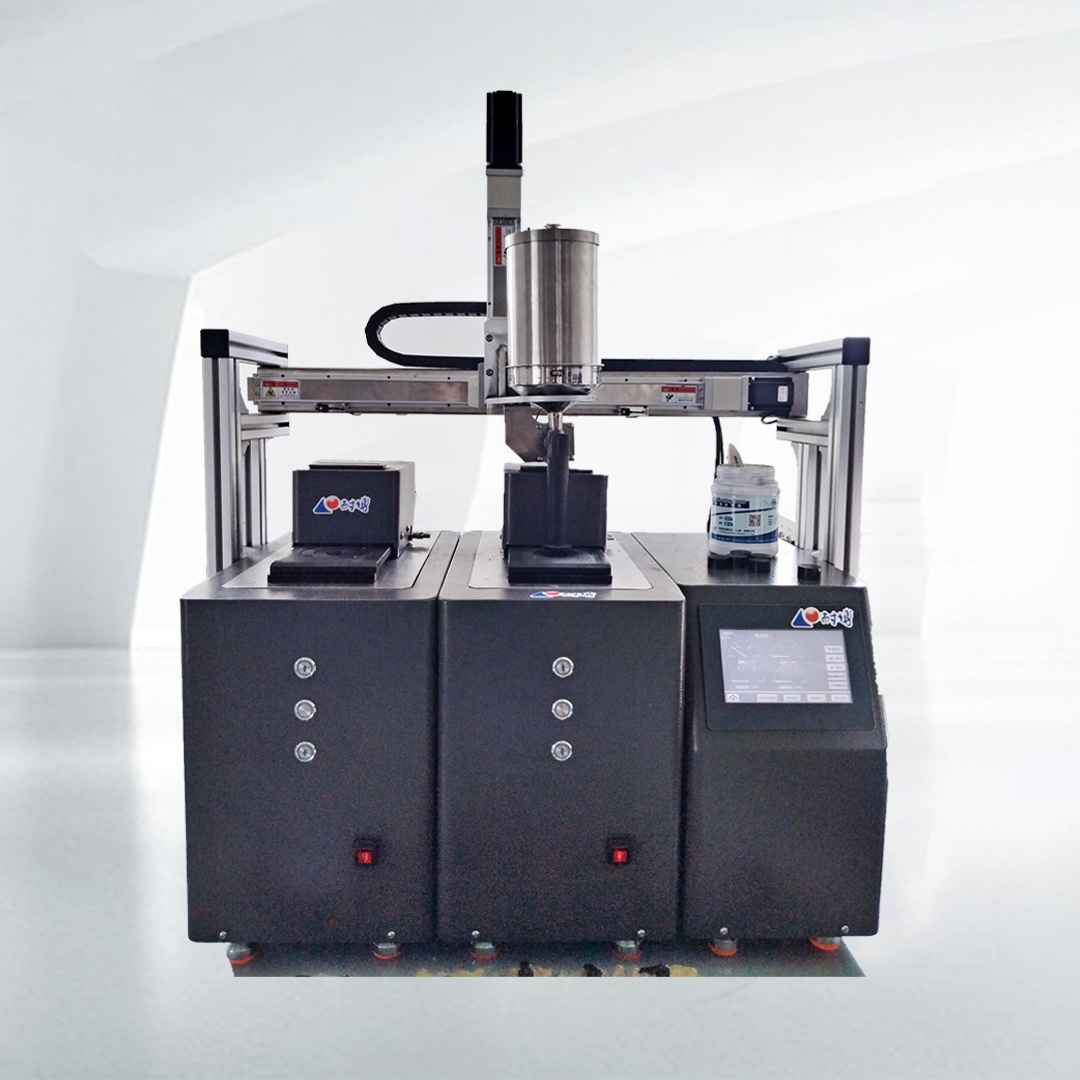

Automatic/manual X-axis parallel movement of the sample to achieve parallel cutting of the sample (option).

Double knives cut simultaneously, and get two parallel samples at one time (optional).

Automatic sample rotation cutting, effectively reducing sample heating (optional).

Classification:

Benchtop Cut-off Machines

Keyword:

Automatic Precision Cutting Machine

Automatic High Speed Precision Cut-off Machine

iMC-250

The spindle adopts servo control, high speed, stepless speed regulation, overload protection.

Innovative Y-axis intelligent cutting method, automatically and quickly finds the cutting starting point, automatically adjusts the cutting speed according to the load, and automatically ends the cutting when the cutting is completed.

Traditional Y-axis manual, automatic, impact and other cutting methods.

Automatic/manual X-axis parallel movement of the sample to achieve parallel cutting of the sample (option).

Double knives cut simultaneously, and get two parallel samples at one time (optional).

Automatic sample rotation cutting, effectively reducing sample heating (optional).

Classification:

Benchtop Cut-off Machines

Keyword:

Automatic Precision Cutting Machine

Product Description

| Model | iMC-250 |

| Cutting blade | Recommended size is φ250xφ32x1.2. Other sizes with diameter less than 250mm can be customized. |

| Cutting disc types | Diamond, CBN and resin cutting discs |

| Spindle speed | 20-3000r/min (optional 50-5000r/min), stepless speed regulation |

| Feed speed | 0.01-5mm/s |

| Manual feed speed | 0-5mm/s |

| Reverse speed | 0-5mm/s |

| Impact cutting distance | 0.1-2mm |

| Cutting stroke (Y axis) | 200mm |

| Cutting stroke (X axis) (option) | 40mm |

| Automatic door opening device (option) | Electric push rod |

| Automatic clamping device (option) | 240N |

| Automatic cleaning device (option) | Single channel |

| Sample rotation (R axis) (optional) | 0-30 (rpm), stepless speed regulation |

| Sample thickness when double-blade cutting (optional) | 2-16mm (increases by 2mm per level) |

| Maximum cutting diameter | Φ85mm, square 78X125mm |

| Maximum clamping length of the workbench | 150mm (customizable) |

| Maximum clamping width of the workbench | 280mm (customizable) |

| Motor power | 1.5kw, optional 2.6kw |

| Cutting parameters | Can store 99 types |

| Power supply | AC220V 50HZ |

| Overall dimensions (width x depth x height) | 865x880x510mm (940x880x510mm for automatic X-axis) |

| Weight | 146KG |

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!