LATEST NEWS

Press releases & Product news

2025 Shanghai Fastener Exhibition|LABTT makes a grand debut with full-process testing solutions

2025-06-18

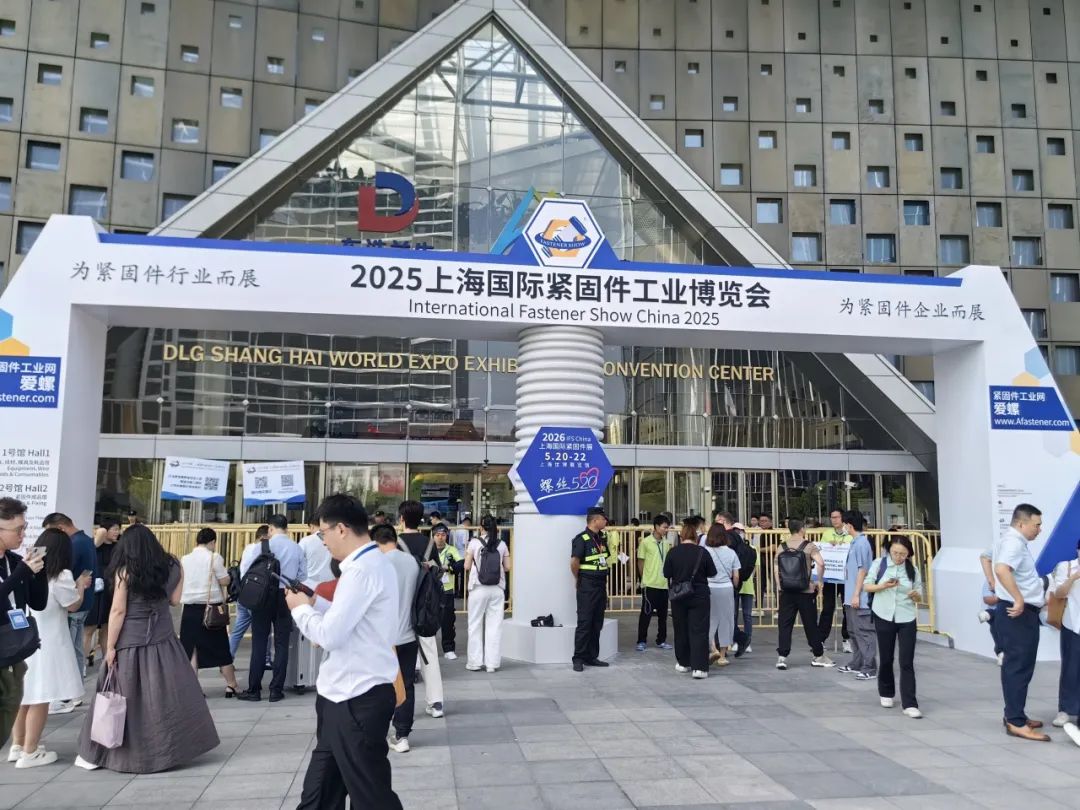

From May 22nd to 24th, the 2025 Shanghai International Fastener Industry Expo opened grandly. As a weathervane of the fastener industry, this exhibition brought together many top companies to fully present the latest achievements in fastener materials, equipment, technology and innovative applications.

LABTT made a strong appearance with its full-process metallographic and hardness testing solutions for fasteners. From cutting, inlaying, grinding and polishing, hardness testing to microscopic analysis, LABTT's self-developed and self-produced metallographic and hardness equipment were exhibited to provide full-dimensional quality assurance for each fastener from raw materials to finished products.

Automatic High-speed Precision Cutting Machine

The LC-200XP automatic high-speed precision cutting machine exhibited this time adopts the Y-axis automatic feed design, standard X-axis translation function, and optional R-axis automatic rotation module and double-blade cutting system. The equipment supports multi-dimensional customized configuration, can accurately adapt to the processing needs of various materials, and achieve efficient and precise cutting.

Automatic Light-curing Cold Mounting Press

The LUM-6000S automatic light-curing cold mounting press independently developed by LABTT adopts a unique low-temperature mode, which can effectively protect temperature-sensitive materials during the sample mounting process.

After the mounting is completed, the mounting chamber door can be opened and closed automatically without manual intervention, accompanied by sound and light reminders, which improves the operating experience in all aspects.

Fully Automatic Metallographic Grinding and Polishing Machine

This grinding and polishing machine adopts a central loading force design, fixes six samples at a time, and completes the grinding and polishing process automatically, ensuring that each sample presents a complete plane, greatly improving the grinding and polishing efficiency. The grinding and polishing disc and the sample disc are independently controllable, and various parameters such as speed and grinding and polishing time can be adjusted at will to meet the needs of various experiments.

Bolt Hardness Tester

LABTT specially exhibited the THR-DX-Z Bolt Hardness Tester for this fastener exhibition, which is a highly efficient testing solution customized for the fastener industry. Equipped with a special bolt fixture, the unique design is suitable for a variety of bolt specifications to ensure testing stability and data accuracy; one-button operation, fast measurement of fastener hardness, and improved testing efficiency.

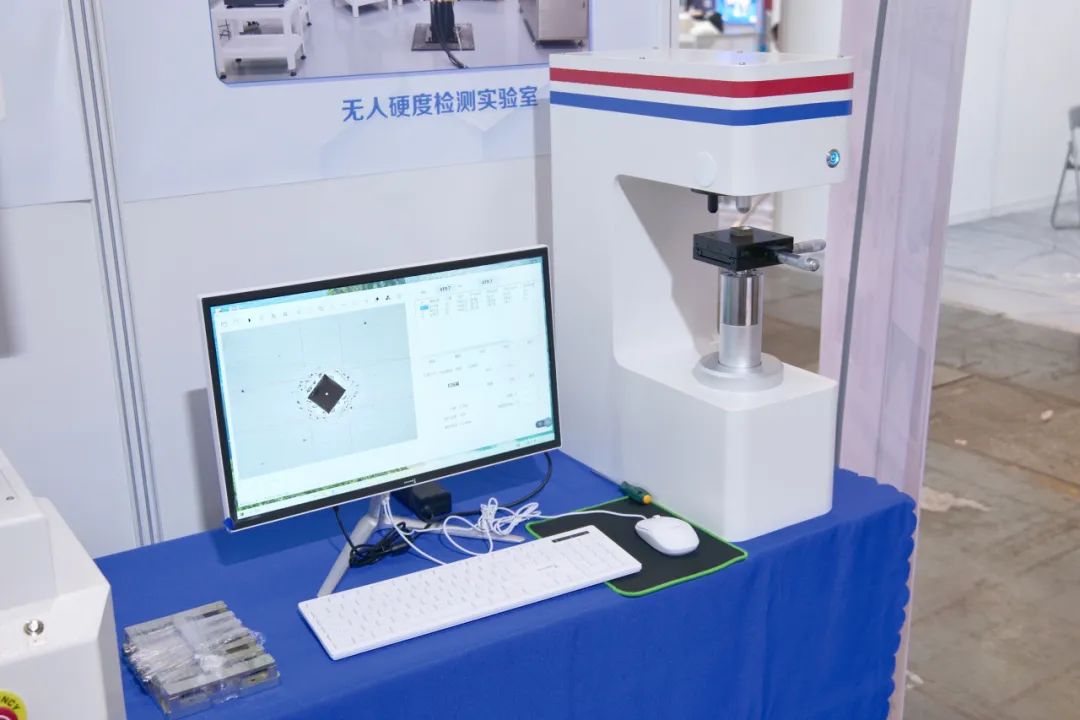

Micro Vickers Hardness Tester

THV-1MPE exhibited this time is a high-value product of LABTT. Its integrated minimalist appearance design is simple yet elegant, and perfectly combines beauty and practicality. The built-in 5 million high-definition camera can present a clearer image without missing any details. It is equipped with a brand computer and dedicated control measurement software, providing users with a convenient and efficient data processing and analysis experience.

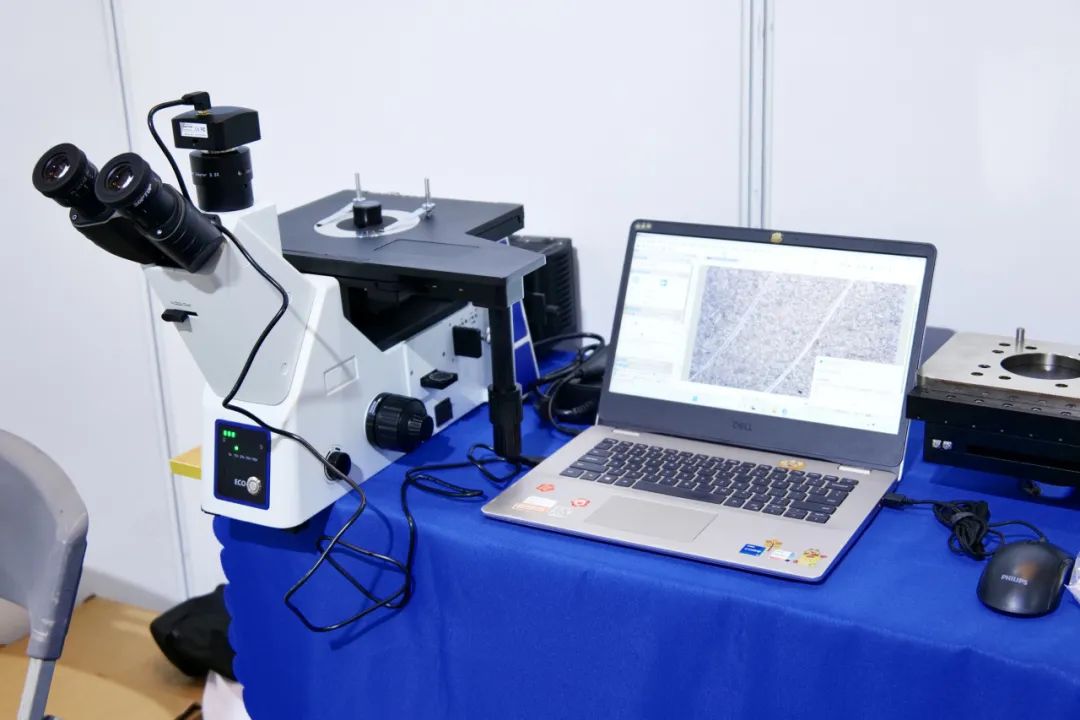

Metallographic Microscope

LABTT M-50BD advanced bright and dark field metallographic microscope, newly designed infinity optical system, ergonomic 360° rotating binocular observation tube, low hand position operation mode, meet the needs of users for long-term observation. It can meet a variety of observation methods: bright field, dark field, simple polarization, differential interference, etc. It can be widely used in casting, smelting, heat treatment research, raw material inspection or material processing analysis and other tests.

LABTT takes "full-process quality inspection" as its core, and provides fastener manufacturing with precise quality control solutions from raw materials to finished products through its independently developed metallographic and hardness testing equipment. In the future, LABTT will continue to deepen technological innovation and work with industry partners to jointly promote the fastener industry to move towards higher precision and greater intelligence.