LATEST NEWS

Press releases & Product news

How to solve the problem of cutting long-axis metallographic specimens?

2025-06-19

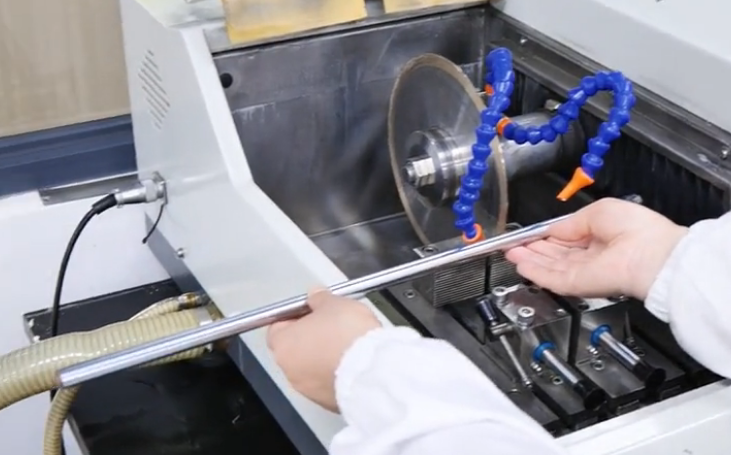

In the field of material testing, the cutting of long-axis metallographic specimens (such as bars and tubes) has always been a headache - unstable clamping, damage to the cutting surface, uneven thermal stress, insufficient cooling... How to efficiently complete the cutting and ensure the quality of the sample? Today we will share a set of systematic solutions to help you easily cope with the challenge!

1.Poor clamping stability

The sample is long, and ordinary clamps are difficult to apply force evenly, which is easy to loosen or offset, causing the cutting surface to tilt or even damage the equipment jaws.

Solution: Segmented clamp + multi-point support

Use multi-segment V-block clamps to apply force evenly along the length of the sample to reduce bending deformation. For extra-long samples, auxiliary support frames can be added to avoid vibration of the overhanging part.

2.Thermal stress concentration causes phase change

The heat diffuses slowly along the long axis, and local overheating may cause changes in material structure and affect the accuracy of analysis.

Solution: Intermittent cutting method

Pause for a few seconds after each cutting to promote heat dissipation and avoid heat accumulation.

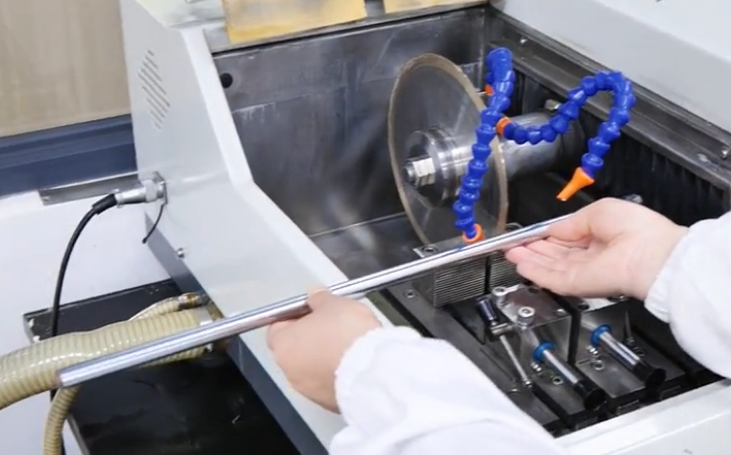

3.Uneven coverage of coolant

The cutting area has a large span, and the coolant is difficult to cover continuously. The risk of dry cutting is high, which aggravates tool wear.

Solution: High-flow directional spray

Adjust the nozzle position to ensure that the coolant continues to cover the cutting area.

4.Equipment space limitation

The ordinary cutting machine has insufficient stroke, and extra-long samples need to be clamped multiple times, which reduces efficiency and accuracy.

Solution: Choose an extended metallographic cutting machine

Preferably choose a model with a soft rubber curtain on the side to expand the cutting space and avoid interference between the sample and the equipment. A large-stroke workbench or movable design is suitable for samples of different lengths to reduce repeated clamping.

5.Bending vibration causes cutting defects

The sample is easy to bend due to its own weight or cutting force, and the cut surface is prone to wavy lines and cracks, which affects subsequent sample preparation.

Solution: Fine adjustment of cutting parameters

Reduce the feed speed to reduce the impact of cutting force on the sample. Choose a suitable grinding wheel according to the material properties, such as resin grinding wheel to reduce the risk of edge collapse.

The cutting of long-axis samples is not unsolvable. Through equipment selection upgrades, fixture optimization, cooling control and parameter adjustment, it can not only improve cutting efficiency but also ensure sample quality. If you have encountered similar problems, please leave a message or contact our technical team to get a customized solution!

PREVIOUS: