LATEST NEWS

Press releases & Product news

How to minimize the damage to the cut surface of metallographic specimens? 5 key points to know!

2025-06-19

In metallographic analysis, sample cutting is the first and most critical step. A perfect cutting surface can lay a good foundation for subsequent grinding and polishing. So, how can we obtain a cutting surface with minimal damage? Let's talk about this topic today.

1. Choosing the right equipment is critical

Precision cutting machine is the first choice! Compared with ordinary cutting machines, it can provide more stable speed control, more accurate feed control, and better shock absorption effect.

These can effectively reduce vibration damage during cutting. The automatic high-speed precision cutting machine produced by LABTT will automatically adjust the feed speed and speed during cutting, and automatically detect and retract the cutter head after cutting. It is an ideal cutting and sample making equipment.

2. Cutting blades are particular

Recommended: ultra-thin diamond cutting blades (about 0.3mm),

Cubic boron nitride (CBN) cutting blades. These high-hardness cutting blades can reduce material removal, reduce mechanical stress, and obtain smoother cuts.

3. Parameter settings should be scientific

Remember these golden parameters: rotation speed: 200-500rpm, feed speed: 0.01-0.05mm/s, and moderate cutting depth. The harder the material, the more "gentle" the parameters should be.

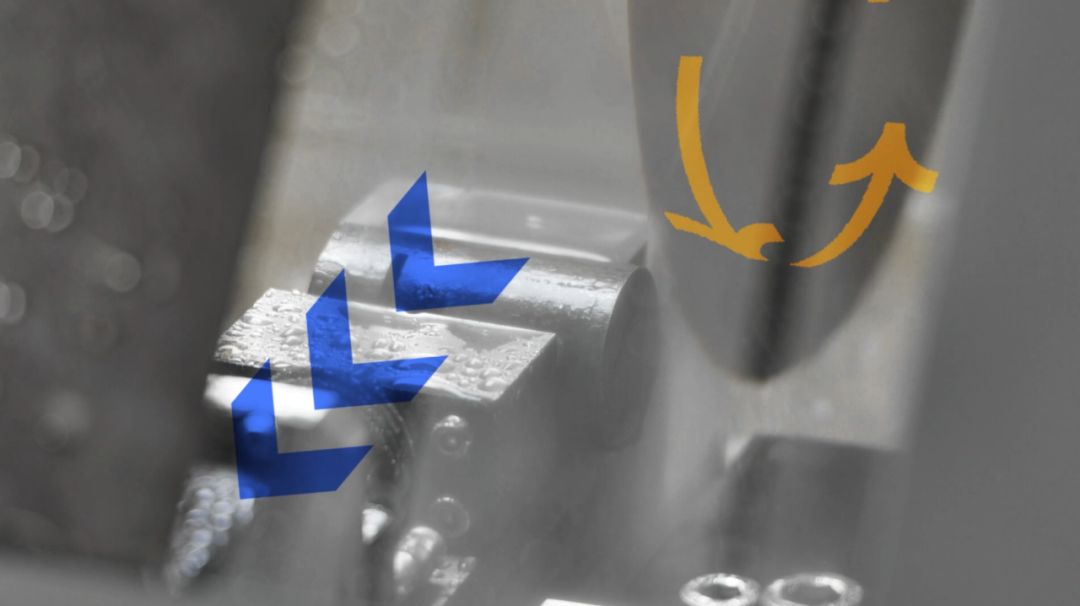

4. The cooling system cannot be ignored

Pay attention to cooling: choose a suitable coolant (water-soluble or oil-based), ensure sufficient flow, and aim the spray at the cutting point, so as to effectively prevent the sample from overheating.

5. The fixing method is very important

When fixing the sample: use a special clamp, the clamping force should be moderate, special-shaped samples can be embedded, and a stable fixation can avoid vibration damage.

Tips:

It is recommended for beginners to practice with small samples

Record each cutting parameter

Test special materials first

Master these 5 key points, and I believe you can also cut out perfect metallographic specimens! If you encounter any problems during operation, please leave a message and we will answer you as soon as possible.