NEWS

Press Releases & Product News

2025-11-07

From October 17th to 19th, 2025, the Shanghai Huamo Auto Parts Exhibition was held at the National Exhibition and Convention Center. As a major industry event, it brought together numerous cutting-edge technologies and innovative achievements in the auto parts field. LABTT showcased its advanced hardness and metallographic testing equipment at the exhibition, injecting new momentum into quality control in the auto parts industry with its precise and efficient product performance.

2025-11-07

On September 20th, the 2025 World Manufacturing Convention and Anhui International High-end Equipment Manufacturing Expo were grandly held at the Hefei Binhu International Convention and Exhibition Center. The convention brought together top manufacturing experts, cutting-edge technologies, and high-end equipment to jointly explore industry breakthroughs and chart an innovative future.

2025-09-22

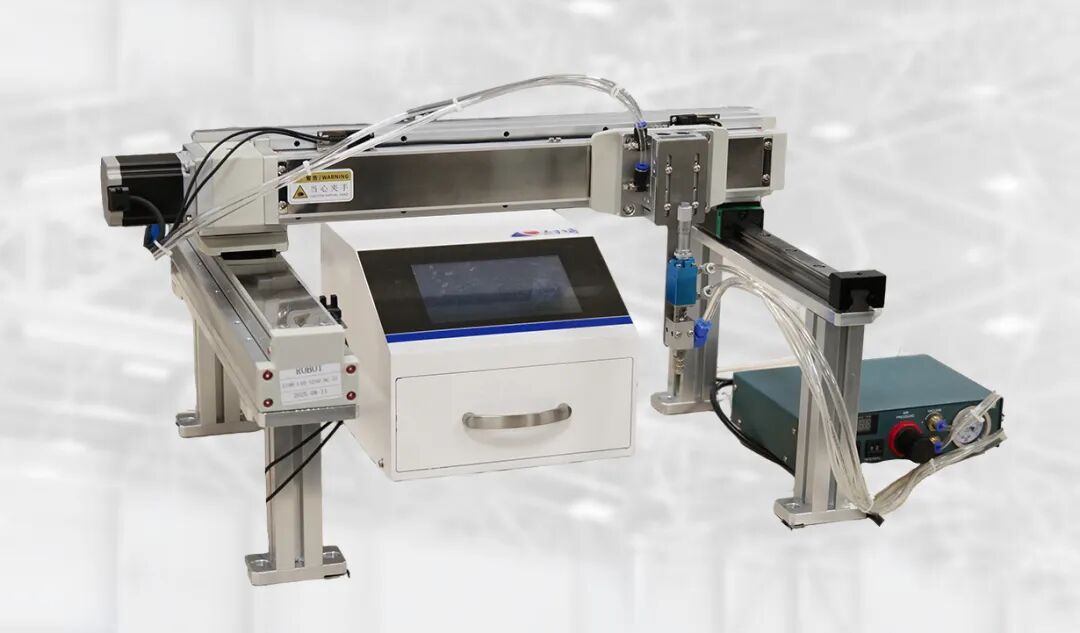

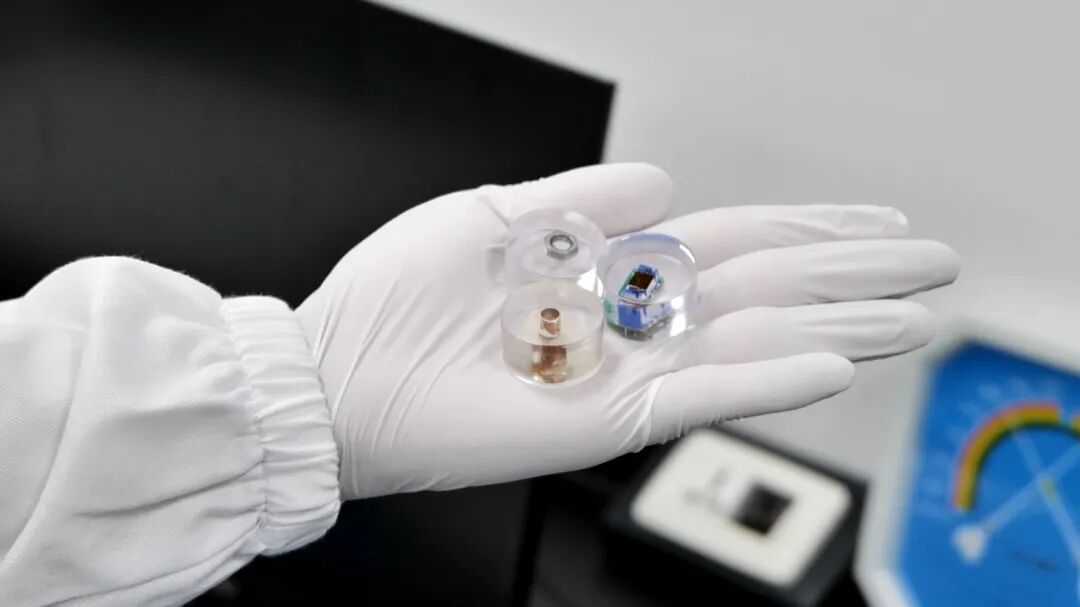

In the metallographic sample preparation process, sample mounting is the most fundamental yet time-consuming step, a long-standing challenge for practitioners. Traditional manual operations are not only inefficient but also suffer from poor repeatability and high quality fluctuations. Now, LABTT's newly launched LUM-9000 fully automatic light-curing cold mounting system offers a brand-new solution for the industry!

2025-09-22

In the steel industry, the quality of metallographic sample preparation is directly related to the accuracy of material property assessment and analysis. However, traditional metallographic sample preparation relies on manual labor, resulting in low efficiency and poor consistency. This is particularly time-consuming and labor-intensive when dealing with large quantities of large-scale samples, a major pain point for many steel mills.

2025-09-22

Metallographic cold mounting is a critical step in material preparation. A high-quality mounting result requires standardized operation and meticulous control. From sample pretreatment, resin mixing, mold positioning, to final demolding, every step directly impacts the success of the mounting. Below, these practical tips will help you easily improve mounting quality and eliminate common defects!

2025-09-22

In the complete metallographic sample preparation process, we often focus on meticulous polishing and precise etching, but often overlook the first and most crucial step: cutting. Standardized sampling directly determines the smooth progress of subsequent sample preparation and, ultimately, the authenticity and reliability of the final microscopic results.

2025-09-22

Always confused about metallographic samples? These 5 marking methods are essential lab essentials!

Have you ever struggled with how to mark your metallographic samples? Different material properties, experimental conditions, and storage requirements often necessitate choosing the most appropriate marking method. Below are five common metallographic sample marking methods for your reference.

2025-09-22

It's only one-third the size of a thumb, yet it supports a 10,000-ton bridge; it silently guards every takeoff and landing of an airplane. Today, let's use metallographic examination technology to uncover the microscopic secrets of this tiny screw!

2025-09-22

Can you just mount your sample after cutting it? Not necessarily! Have you ever, or are you still, skipping pre-treatment steps? You know, proper pre-mounting preparation directly determines the success or failure of subsequent polishing, observation, and even electron microscopy analysis—especially for complex samples. A little carelessness can affect imaging at best, or even mislead conclusions at worst. Today, we'll systematically review the essential pre-mounting considerations.

2025-08-22

Have you ever encountered this problem during metallographic sample preparation? After repeated grinding and polishing, the sample surface is either raised or recessed, never achieving the desired smoothness. This common "relief" problem can be a real headache, but don't worry! Today, we'll explain the causes in detail and provide professional and reliable solutions.